AISI 1018 Carbon Steel

AISI1018 Carbon Steel is a low carbon steel which is characterized by good weldability, good machinability, high strength and impact properties in either the normalized or hot forged condition. SAE1018/AISI1018 steel is widely used for screw machine parts, shafts, pins, spindles and rods.

What is AISI 1018 Carbon Steel?

AISI 1018 is a low-carbon steel with a carbon content of approximately 0.18%. It is a general-purpose steel used in applications that do not require high strength or wear resistance. The material is particularly well-suited for machining and cold-forming operations, making it a favorite for precision parts manufacturing.

Chemical Composition

The properties of AISI 1018 are defined by its simple, low-carbon composition:

| Element | Content (%) |

|---|---|

| Carbon (C) | 0.15–0.20 |

| Silicon (Si) | 0.10–0.30 |

| Manganese (Mn) | 0.60–0.90 |

| Phosphorus (P) | ≤ 0.040 |

| Sulfur (S) | ≤ 0.050 |

This low-carbon content contributes to its excellent weldability and ductility.

Mechanical Properties

AISI 1018 provides a balanced set of mechanical properties, which can be enhanced with heat treatment:

| Property | Cold-Drawn | Hot-Rolled |

|---|---|---|

| Tensile Strength | 440–480 MPa | 370–440 MPa |

| Yield Strength | 350–400 MPa | 220–320 MPa |

| Elongation at Break | 15–17% | 20–25% |

| Brinell Hardness (HB) | 120–150 | 105–130 |

Cold-drawn 1018 offers improved mechanical properties compared to hot-rolled, making it a preferred choice for precision applications.

Key Features and Benefits

- Excellent Machinability:

- One of the most machinable low-carbon steels, allowing for precise and efficient manufacturing.

- Good Weldability:

- Can be welded using various methods without the need for preheating or special precautions.

- Ductility and Toughness:

- The low carbon content ensures high ductility and resistance to brittle fractures.

- Ease of Forming:

- Ideal for cold-forming operations such as bending, stamping, and drawing.

- Cost-Effectiveness:

- Provides reliable performance at an economical price, making it suitable for large-scale manufacturing.

Applications of AISI 1018 Carbon Steel

Due to its balanced properties, AISI 1018 is used across multiple industries for various applications:

- Automotive Components:

- Shafts, axles, and bolts.

- General Engineering:

- Machine parts, spindles, and pins.

- Construction:

- Structural reinforcements and fasteners.

- Tooling Applications:

- Low-stress jigs, fixtures, and tooling plates.

- Precision Manufacturing:

- Ideal for producing small, precise parts such as gears and bushings.

Heat Treatment of AISI 1018

Heat treatment processes can modify the mechanical properties of AISI 1018:

- Annealing:

- Heating to 870–910°C followed by slow cooling in the furnace. This process softens the steel for improved machinability and ductility.

- Case Hardening (Carburizing):

- Introduces carbon to the surface layer at 870–925°C, followed by quenching. This creates a wear-resistant surface while maintaining a tough core.

- Normalizing:

- Heated to 900–950°C and air-cooled to refine grain structure and improve uniformity.

- Stress Relieving:

- Performed after machining to reduce residual stresses and improve dimensional stability.

Processing Techniques

- Machining:

- AISI 1018 is well-suited for high-speed machining, delivering smooth finishes and precise tolerances.

- Welding:

- Commonly welded using MIG, TIG, or arc welding. No preheating is generally required.

- Cold Working:

- Easily bent, drawn, or stamped due to its high ductility.

- Hot Working:

- Can be forged at 1,200–950°C, followed by air cooling or annealing.

Comparisons with Similar Grades

| Steel Grade | AISI 1018 | AISI 1020 | AISI 1045 |

|---|---|---|---|

| Carbon Content | Low (0.15–0.20%) | Low (0.18–0.23%) | Medium (0.43–0.50%) |

| Strength | Moderate | Slightly Higher | High |

| Weldability | Excellent | Excellent | Moderate |

| Applications | General-purpose | Slightly stronger parts | High-stress components |

Certifications and Standards

To ensure quality, ensure compliance with recognized standards:

- ASTM A108: Specification for carbon steel bars, cold-finished.

- SAE J403: Chemical compositions for carbon steels.

- DIN EN 10025-2: Technical delivery conditions for non-alloy steels.

AISI 1018 Carbon Steel – The Complete FAQ Guide

You might know what AISI 1018 carbon steel is, but do you know where you can get the highest quality of this particular material?

For our guide today, apart from educating and teaching you all the information you need to know about AISI 1018 carbon steel, we’ll also assist you for you to find the best AISI 1018 carbon steel manufacturer!

Regardless of your experience in the steel industry, by the end of this guide, you will be an expert in distinguishing what AISI 1018 carbon steels are from its counterparts!

What is AISI 1018 Carbon Steel?

AISI 1018 carbon steel is a type of carbon steel that’s mild or low, that contains high levels of weldability and machinability.

You would want to utilize AISI 1018 carbon steel if you want steel that has a good level of case hardening qualities. Furthermore, you can best use 1018 carbon steel if you need to perform procedures requiring cold forming like bending, crimping, swaging, etc.

What Does AISI 1018 Mean?

In understanding, let us dissect the term one-by-one.

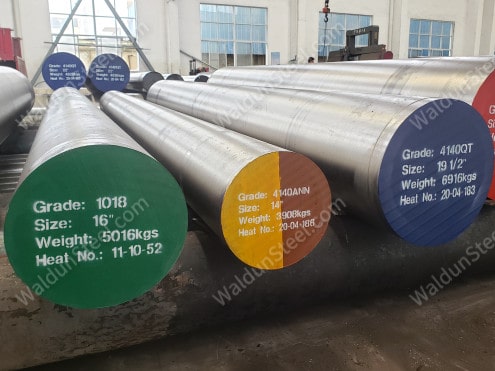

1018 carbon steel being prepared

AISI is a shortcut term for the American Iron and Steel Institute or AISI, and 1018 is the steel grade that discusses the overall content and coverage of alloying elements.

Dissecting the AISI Naming System

Part of the most common series of steel is the carbon steel series. These are series that are 1XXX. The first and second digits contain the type of steel.

For instance, 10XX means that it’s plain carbon steel, 12XX means that it’s resulfurized, 15XX mean that it’s plain carbon steel with Manganese levels that range between 1.00 and 1.65%, etc.

The third and fourth digits, on the other hand, simply dictate the amount of carbon present in the steel times 0.01%.

Therefore, we can conclude that the AISI 1018 carbon steel is a steel type that is made from plain carbon steel with 0.18% carbon. AISI 4140, on the other hand, is a type of Chromium-Molybdenum steel that contains 0.40% carbon.

What is the Carbon Content of AISI 1018 Mild Steel?

As discussed above, the carbon content of AISI 1018 mild steel is easily known by looking at the last two (2) digits multiplied by 0.01%, which is 0.18%.

What is the Maximum Manganese Content of 10XX Steels?

The maximum manganese (Mn) content of this particular steel family is 1.00% max. In case you’re not aware, manganese is the one responsible for the improvement or the development of the mechanical properties of steel.

In addition to that, you can also hold it responsible for the decrease or the reduction of the critical cooling rate.

What is the Difference Between 1018 and 1045 Steel?

If we were to base it from the knowledge we’ve gotten above, then both 1018 and 1045 carbon steels are from the same family.

1045 carbon steel in round bar form or shape

The only difference is that AISI 1018 carbon steel contains 0.18% carbon content. On the other side of the ring, 1045 carbon steel has 0.45%.

What this means is that in terms of tensile strength and general strength, 1045 would be the better option to take. But, that does not make AISI 1018 carbon steel less of the steel that we know of.

In fact, you wouldn’t find SAE 1045 steel effective if you were to use it for welding and machining processes; you would not be able to use it like how you would utilize AISI 1018 carbon steel.

We can therefore conclude that 1045 carbon steel might be the stronger and more durable type of steel, but it wouldn’t be the most useful for applications where both tensile and yield strength aren’t important.

Is Low Carbon Steel Strong?

Before we discuss it, let us try to differentiate low, medium, and high carbon steels.

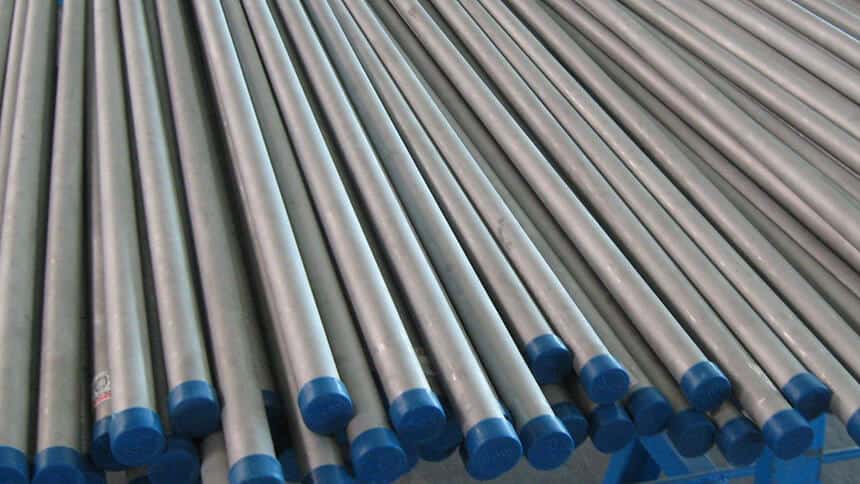

Image of low carbon steel sheets

- Low carbon steels are the steel grades that contain 0.30% or less carbon.

- Medium carbon steels are the steel grades that have 0.30% to 0.60% carbon.

- High carbon steels are those that offer 0.60% carbon and above.

Low carbon steel, also known and referred to as mild steel or plain-carbon steel is considered to be one of the most common types and forms of steel.

Yes, mild steel or low carbon steels are actually still strong, given the fact that they contain carbon. However, if they’re put side-by-side with medium-carbon and high-carbon steel, their differences in strength will be more apparent.

The main advantage that low carbon steels like AISI 1018 is that they’re ductile and malleable. Basically, they’re more workable when it comes to machinability and weldability that medium and high-carbon content steels.

What is High Carbon Steel Used For?

Since high-carbon steels are the steels that contain the highest tensile strengths, you can make use of them in a wide array of applications.

Gears – one of the most common applications of high carbon steel

But, the most common applications high carbon steels have include, but are not limited to:

- Rail Steels

- Wear Resistant Steels

- Tire Reinforcement

- Strength Bars

- Cutting Tools

- High-Strength Wires

- Punches and Dies

- Axles

- Pipelines and Couplings

- And Many More!

If you notice, all these applications require solid steel.

And while some of it are parts and components that low-carbon steel is able to accommodate, you’ll be able find using high-carbon steels better and more durable.

What is the Density of AISI 1018?

The density of AISI 1018 carbon steel is at 7.87 g/cm3. Contrary to popular belief, the density of steels actually depends on the elements that are contributing to its overall composition.

If we are to look at the usual and the general density, though, it will be within 7.750 to 8.050 kg/m3.

Characteristics of AISI 1018 Carbon Steel

This low-carbon mild steel boasts of its characteristics of being an overall or general-purpose type of steel.

AISI 1018 carbon steel is all-around and multipurpose

Regardless of that, here are some other traits and characteristics you can have with it:

Suitable For Cold Forming/Rolling

Unlike many steels, AISI 1018 carbon steel is also capable of being cold rolled or formed. Its hot rolled form or state is the more common and the easier option, but cold forming or cold rolling is available, too.

Easy-to-Form

Since their hardness levels aren’t that high, you can expect that they wouldn’t easily break when pressure is applied.

The truth of the matter is, AISI 1018 carbon steels are easier to machine, weld, and form than medium or high-carbon steel materials.

Pre and Post-Heating is Not Required

Last but definitely not least is the fact that you don’t really need to preheat AISI 1018 carbon steel in preparation for welding. On the opposite end of the rope, you don’t need to perform post-heating procedures to retain its traits and characteristics.

These are just some of the most customary and the most common traits and characteristics of the AISI 1018 carbon steel. There are others more and that’ll depend on how you plan on using it!

How Hard is 1018 Steel?

Since hardness can be determined and distinguished in different ways, the Rockwell hardness of the AISI 1018 carbon steel is between 71 and 78 based on the Brinell hardness scale.

What this means is that it’s capable of resisting impact and other types of possible-damage instances and scenarios, all the while having high levels of machinability and weldability.

Is Carbon Steel Harder Than Stainless?

Yes, carbon steel – whether it’s low-carbon steel, medium-carbon steel, or high-carbon steel – is a lot harder and stronger than stainless steel.

Thanks to the significant levels of carbon, carbon steels have higher and better tensile strengths than stainless steel.

The only drawback of this hardness is that they’re less ductile and less malleable than stainless steels. What this means is that stainless steels are steels that you can find to be easily molded, welded, machined, formed, etc.

AISI 1018 Equivalent

There are multiple equivalents of the AISI 1018 carbon steel. In the EN standard, it’s known as the EN32B steel. In the UNS standard, on the other hand, it is the G10180 steel.

Does Equivalent Steel Mean They’re 100% Identical?

A lot of people think that when it’s tagged and deemed as “equivalent,” they’re 100% the same. But, they’re actually not.

Steel grades are separated in different standards, and more often than not, these standards are categorized in each region of the world. The Chinese has its own standard, the Europeans have their own, the Americans have their own, and so forth.

You can understand them as “equivalents” because they have the same alloying elements. But they don’t contain the same levels.

AISI 1018 Hot Rolled Steel Properties

Being cold and hot rolled would have different properties because they’re not identical in terms of temperature, hardness, elongation, and the like.

Here’s a quick overview of the properties of hot rolled AISI 1018 carbon steel:

- Tensile Strength – 67000 psi

- Elongation –36%

- Yield Strength – 45000 psi

- Melting Point – 1,480 to 1,526 degrees Celsius

- Thermal Conductivity – 25 to 93 W/(m-K)

- Elastic Modulus – 210 GPa

Does AISI 1018 Have Good Weldability?

Yes, as a matter of fact, AISI 1018 carbon steel is the steel grade that you can count on to give you the most balanced properties.

It’s strong, tough, ductile, malleable, and completely weldable and formable all at the same time.

When you get it in its hot rolled form, you can obtain better and more developed mechanical, machining, and welding capacities and properties.

Is AISI 1018 Low Carbon Steel Corrosive Resistant?

Yes, AISI 1018 mild steel or low-carbon steel is capable of resisting rust. However, if we put it into perspective, its corrosion resistance levels are lower and are less reliable compared to the other steel grades in its playing field.

In fact, in the most aggressive environments, the AISI 1018 carbon steel might not be very useful in resisting against oxidation and rusting.

Based on one study, the AISI 1018 steel was the one that has shown the highest rate of corrosion. Meaning, it was the steel grade that has deteriorated in a fashion in which it’s exposed to oxygen.

Overall, AISI 1018 mild steel is corrosion resistant in non-extreme and non-harsh environments.

Can You Manually Bend an AISI 1018 Steel Pipe?

Yes, as a matter of fact, you can bend AISI 1018 carbon steels the same way of how you bend regular steel.

However, it is imperative that before bending, you know the true minimum-bending radius of the AISI 1018 mild steel you’re dealing with.

AISI 1018 Carbon Steel Manufacturers

Choosing the best 1018 steel supplier will be as important as getting the highest quality of the steel simply because of the fact that your business will rely on the capability of them.

If you choose to work with an AISI 1018 carbon steel manufacturer that’s not capable of producing the required amount per day, you might put yourself or your business in grave danger.

Here in the country of China, no other AISI 1018 carbon steel manufacturer is trusted but us here at Waldun Steel. For many years, we’ve proven our ability and our mastery in the production or the manufacturing of AISI 1018 carbon steel.

Why Waldun Steel is the Best AISI 1018 Carbon Steel Manufacturer

While you have numerous options to go with in the market, there are a million reasons why you need to consider working with us here at Waldun Steel for your AISI 1018 mild steel.

Some of these reasons are:

- We utilize high-quality machinery and equipment like a miller, vertical lathe, horizontal lathe, etc.

- We are capable of performing machining capacity of 20,000 tons per year

- We house a Research & Development (R&D) team that can accommodate to your requests

- Rest assured that we perform complete and comprehensive heat treatment of your steel

You will never find another AISI 1018 carbon steel supplier as trusted and as reliable as us here at Waldun Steel!

Get Engineering Steels, High-Speed Steels (HSS), Tool Steels, and many more from us!

Page Contents

- What is AISI 1018 Carbon Steel?

- Chemical Composition

- Mechanical Properties

- Key Features and Benefits

- Applications of AISI 1018 Carbon Steel

- Heat Treatment of AISI 1018

- Processing Techniques

- Comparisons with Similar Grades

- Certifications and Standards

- AISI 1018 Carbon Steel – The Complete FAQ Guide

- What is AISI 1018 Carbon Steel?

- What Does AISI 1018 Mean?

- What is the Carbon Content of AISI 1018 Mild Steel?

- What is the Maximum Manganese Content of 10XX Steels?

- What is the Difference Between 1018 and 1045 Steel?

- Is Low Carbon Steel Strong?

- What is High Carbon Steel Used For?

- What is the Density of AISI 1018?

- Characteristics of AISI 1018 Carbon Steel

- How Hard is 1018 Steel?

- Is Carbon Steel Harder Than Stainless?

- AISI 1018 Equivalent

- AISI 1018 Hot Rolled Steel Properties

- Does AISI 1018 Have Good Weldability?

- Is AISI 1018 Low Carbon Steel Corrosive Resistant?

- Can You Manually Bend an AISI 1018 Steel Pipe?

- AISI 1018 Carbon Steel Manufacturers

- Why Waldun Steel is the Best AISI 1018 Carbon Steel Manufacturer