High Speed Steel – The Comprehensive FAQ Guide

Are you looking for a supplier or a manufacturer of high speed steel that you can trust? If you are looking for more information about what high-speed steel is, you’re just in the right page!

In this guide, you will not only learn what high speed steel is; we’ll also give you the know-how of getting or working with a high-speed steel supplier or manufacturer!

What is High Speed Steel or HSS?

High speed steel, or HSS for short, is part of the alloy family.

what is high speed steel or hss

Image of what High Speed Steel or HSS looks like

It’s an alloy where they’re able to get their properties from a wide array of alloy metals; these alloy metals are usually substances that you add to carbon steel, such as molybdenum and tungsten.

In addition to that, it’s part of a subset of tools that you use for cutting; the most common use for it is with drill bits and blades.

What is High Speed Steel Made Of?

The main composite of high speed steel is molybdenum and tungsten with carbon steel. But. More often than not, these materials are mixed and combined with cobalt and vanadium.

These elements actually increase the working temperature of HSS; it’s what will make your high speed steel be workable in temperatures that can go as high as 650 degrees Celsius.

Advantages and Pros of Using High Speed Steel

pros and advantages of high speed steels (hss)

HSS has high levels of wear resistance, that’s why it’s used to produce cutting tools

Using high speed steel can actually get you many different pros and benefits. Some of these benefits include:

High Wear Resistance

One of the many advantages of high speed steel is that it has a high level of wear resistance. Thanks to the heat treatment procedure done in finishing and polishing, HSS has a high level of wear resistance.

More so, the red hardness level of HSS can reach up to 650 degrees Celsius! Use high speed steel to cut temperatures that contains significant temperature levels!

High Cutting Speeds

From its term alone, you already know that you’ll be able to cut in “high speeds,” using HSS. You can definitely enjoy using it if your project requires cutting at fast and swift rates.

Strength and Hardness

Part of the many advantages of using HSS or high speed steel is the hardness of it. Following its wear resistance level, the hardness and the strength of HSS is unmatched because they’re treated under extreme heat applications.

Lower Price

If we look at high speed steel or HSS and line it up with other substances such as tungsten carbide, cemented carbide, and the likes, HSS is a lot cheaper and more workable.

With its price, you will definitely not have any problems finding budget for it.

High Speed Steel Disadvantages

HSS isn’t all rainbows and butterflies. As a matter of fact, there are also some cons and disadvantages to it.

These disadvantages include, but are not limited to:

High Brittleness

HSS is made and is finished through heat treatment – not only is it hard, it’s also going to be a lot more brittle, too. In addition to that, it’s easy to be broken compared to other types of steel!

Low Vibration and Impact Resistance

Because of its hardness, you can expect high speed steel to have low vibration levels. This means that if it’s vibrated without regulation, it can lead to it breaking and cracking.

Moreover, a HSS’s impact resistance isn’t also good compared to other types and kinds of steel.

Poor Red Hardness

You might think that it’s capability and capacity of about 650 degrees Celsius is already good, but it’s not.

Basically, red hardness is a steel’s capability of being heated to red; it’s basically heat resistance.

In fact, you will find higher and more flexible red hardness and temperature capacities with other types of steel. Take tungsten carbide for example; the red hardness of tungsten carbide, it is at about 800 to about 1,200+ degrees Celsius – it’s just half of the red hardness or temperature resistance of HSS.

What is the Melting Point of HSS?

The melting point is the temperature in which high speed steel melts.

what is the melting point of hss

When placed under extreme temperatures, high speed steel (HSS) can be melted

And, to give you the melting point of HSS, it’s going to be around 1,430 degrees Celsius. Depending on the mixture of alloys and other substances, it can go as high as 1,600+ degrees Celsius.

Different Types of High Speed Steel

While many people thought that HSS is only grouped into one (1) type, the American Institute of Steel and Iron (AISI) confirms two (2) basic types of HSS.

different types of high speed steel

Molybdenum (M-Grade) and Tungsten (T-Grade), the major types of HSS

Tungsten Type (T-Grades)

You would want to use the tungsten types of HSS if you’re looking at increased wear resistance and tempering.

This is simply because of the fact that Tungsten contains properties that are resistant to a wide array and classifications of wear.

Molybdenum Type (M-Grades)

Molybdenum HSS types, on the other hand, are the types you want if you are looking to improve and to enhance toughness and strength.

Basically, the number that follows the letter (T or M), does not have a significance other than to identify it from one another.

They run more flexible and more workable than tungsten because of their flexibility and overall toughness. In addition to that, they are less brittle than T-grade high speed steels.

What Do The Numbers After the Letters of High Speed Steel Grade Mean?

To give you a perfect example, M5 does not mean that it’s more alloyed and it’s better than M2, and so on.

What these numbers really mean is in terms of identification and distinction of what the properties of the particular grades are.

M1 is the type that lacks red hardness, but is more flexible; M7 is what you want to use to make and produce heavier construction drills where strength weighs the same as flexibility, M35 is similar to M2 but it has a mixture of cobalt, and so on.

What is M2 High Speed Steel?

M2 HSs is a type of tungsten-molybdenum steel, which has been popular and famous for both cutting and non-cutting applications.

what is m2 high speed steel

M2 high speed steel, one of the most common types of HSS in the market

Compared to other types of steel, M2 high speed steel has a high level of carbon. What does this mean? – it basically means that you’ll be able to use it for better and higher level of wear resistance.

High Speed Steel (HSS) vs. Tungsten Carbide Steel

When selecting tools, you would usually be given the option of working with tungsten carbide or with high speed steel (HSS).

Carbide steel is a type of steel, which is a combination of an alloy metallic element and carbon. High speed steel, on the other hand, is a type of steel that has a ton of cobalt and tungsten in it. More so, it’s also something that’s rich in vanadium, molybdenum, and/or tungsten.

If you’re torn in choosing HSS and tungsten carbide steel, here are some key differences between the two:

- When it comes to cutting speed, tungsten carbide is better. It actually is four (4) to seven (7) times faster than HSS

- Carbide steel’s red hardness is about 800 to 1,200 degrees Celsius, while HSS is at 650

- Tungsten carbide tools are harder and tougher, therefore, they’re more brittle and they’re more likely to break easier

- High speed steel is cheaper and a lot easier to find in the market compared to carbide tools

Does HSS Steel Rust?

While most HSS tools are wear and corrosion resistant, there will come a time when its resistance will deteriorate.

does hss steel rust

High speed steel (HSS) will rust and deteriorate if not cared for properly

What this basically means is that they will rust; even if the alloy chromium content of HSS is high, it’ll still oxidize, causing the material to rust and become corroded.

What are the Applications of High Speed Steel?

When it comes to applications, high speed steels (HSS) will never fail you.

what are the applications of high speed steel

You’ll be able to use high speed steel in a lot of different applications

You can find a ton of different uses and applications of HSS in the market, the most customary ones include, but are not limited to:

Cutting Tools

Because of its hardness and its flexibility, the most common use or application for high speed steel is to create cutting tools.

There are a lot of many different cutting tools available in the market, such as drill bits, circular saw blades, etc.

Milling Materials

Apart from creating or manufacturing drill bits and saw blades, you can also find use for high speed steel in milling cutters.

Milling cutters or milling materials are the cutters that you can use for milling machines.

Punches and Dies

A punch and die is a material that you usually use in forming metal sheets for automotive parts, airspace craft, and many more!

The punch is the part of the team that’s used to bend, stretch, and form, while the die is the one that is the opposite (it’s usually called a “die block).

Taps

A tap is a kind of tool that you can use to create and make screw threads. You usually use it to form the part of a pair that’s the female (like a nut, for example).

While these aren’t the only applications and uses for high speed steel, they’re the most common and you will be able to find many more uses of it when you see it for yourself!

High Speed Steel For Sale

If you’re looking for a high speed steel manufacturer, working with an American or a European supplier might seem to be “the best” choice. But, Asian – particularly Chinese companies can do good too.

So, don’t hesitate to work with a Chinese supplier – you’ll get even better results from them !

Apart from the fact that you’ll be able to get decent and competitive rates and prices, you will also get higher and better quality of HSS with them!

You’ll see a lot of high speed steel for sale postings from Chinese retailers and manufacturers; and you will not have any doubts in working with them.

Should you be the one to prefer purchasing from Amazon, there’s nothing wrong with it. It’s just that, if you purchase directly from an HSS wholesale manufacturing company, you can get big discounts and promotional offers!

HSS Prices and Rates

Purchasing high speed steel as it is, will be cheap. So, let’s say that your business involves the manufacturing of drill bits, you can purchase high speed steel in bulk or in wholesale to get cheaper and more affordable rates.

You can purchase HSS in various shapes, the most common figure you can purchase it in would be in a steel bar or a cylindrically shaped steel bar that can weigh as much as 1,050 kilograms.

But, you can also purchase it in a square or a rectangular bar.

Where Should I Purchase High Speed Steel?

If you are looking for the best and the most reliable Chinese high speed steel manufacturing company, don’t hesitate to work with us here at Waldun.

For more than a decade, Waldun has been considered as the top high speed steel supplier and manufacturer in the whole of China.

Thanks to our experts, we’re able to experiment in terms of producing and manufacturing the high speed steels that you need for your business.

Whether you need a pre-made high speed steel in a steel bar form, or if you need it in a custom form, you can always bank and rely on us!

In our experience of being the number one HSS manufacturer in China, we never failed to satisfy and to meet the needs of our clients. Whatever they asked us, we provided and we are always ecstatic to give them the assistance they’re looking for.

So, if you ever find yourself in need of an HSS manufacturer in China, never hesitate to give Waldun a call or an email.

Also, you can fill out the contact form that we have here on our website to get a free quotation or a free estimate of the orders and the products you need!

Work with us and experience world-class quality high speed steels in the best and the most competitive rates!

High Speed Steel Buying Guide

What is High Speed Steel?

High Speed Steel (HSS) is a tool with high hardness, high bear resistance and high altitude resistance. It is also known as high speed tool steel or sharp steel, common known as white steel.

HSS has good process performance,with good strength and toughness,so it is mainly used to make complex thin-edged and impact-resistant metal cutting tools,and also to make high-temperature bearings and cold extrusion dies,etc.

In addition to the production of high-speed steel by melting,there is also powder metallurgy high-speed steel .It has the advantage of avoiding the carbide segregation caused by the melting method of production,it will cause mechanical properties and heat treatment deformation.

How to produce high speed steel?

The heat treatment process of high speed steel is complicated, must undergo a series of processes such as quenching, tempering, etc. Quenching is generally carried out in two stages due to its poor thermal conductivity. Preheat at 800~850℃(to avoid large thermal stress), Then quickly heated to quenching temperature 1190~1290℃(different grades of actual use temperature difference), After cooling by cold or air cooling or inflatable body cooling. The plants are heated by salt furnaces, Vacuum furnaces are also widely used. After quenching, some (about 30%) of retained austenite is not transformed into martensite, It affects the performance of high speed steel. To convert retained austenite, Further improve hardness and wear resistance, Generally 2~3 tempering, Tempering temperature 560℃, Heat preservation for 1 hour each time.

Manufacturing method: electric furnace is usually used to produce high speed steel, powder metallurgy is used to produce high speed steel, so that the carbides are distributed uniformly on the matrix, which improves the service life.

Purpose: used to manufacture various cutting tools. Such as turning tool, drill bit, hob, machine saw blade and high-demand mold.

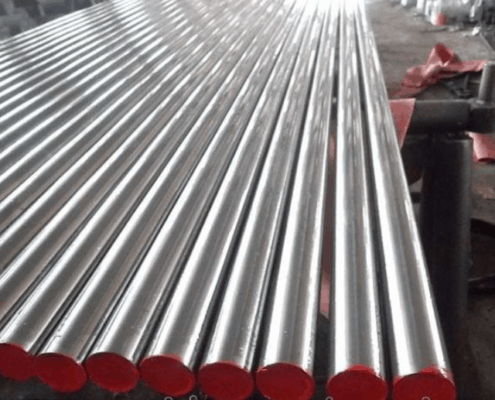

High Speed Steel Specification and Appearance

Specifications are mainly round steel and square steel, plate. The surface of steel should be well processed, without visible cracks, folding, scarring and hair lines. The surface of cold-drawn steel should be clean, smooth, without inclusions and oxide.

What is High Speed Steel Chemical Composition?

| GB | ASTM | C(%) | W(%) | Mo(%) | Cr(%) | V(%) | Co(%) | Si(%) | Mn(%) | S(%) | P(%) | etc |

| W18Cr4V | T1 | 0.70-0.80 | 17.5-19.0 | Max 0.30 | 3.80-4.40 | 1.00-1.40 | – | 0.20-0.40 | 0.10-0.40 | Max 0.030 | Max 0.030 | – |

| W9Mo3Cr4V | 0.77-0.87 | 8.50-9.50 | 2.70-3.30 | 3.80-4.40 | 1.30-1.70 | – | 0.20-0.40 | 0.20-0.40 | Max 0.030 | Max 0.030 | – | |

| W6Mo5Cr4V2 | M2(Regular C) | 0.80-0.90 | 5.50-6.75 | 4.50-5.50 | 3.80-4.40 | 1.75-2.20 | – | 0.20-0.45 | 0.15-0.40 | Max 0.030 | Max 0.030 | – |

| CW6Mo5Cr4V2 | M2(High C) | 0.95-1.05 | 5.50-6.75 | 4.50-5.50 | 3.80-4.40 | 1.75-2.20 | – | 0.20-0.45 | 0.15-0.40 | Max 0.030 | Max 0.030 | – |

| W2Mo9Cr4V2 | M7 | 0.97-1.05 | 1.40-2.10 | 8.20-9.20 | 3.50-4.00 | 1.75-2.25 | – | 0.20-0.55 | 0.15-0.40 | Max 0.030 | Max 0.030 | |

| 9W18Cr4V | 0.90-1.00 | 17.5-19.0 | Max 0.30 | 3.80-4.40 | 1.00-1.40 | – | Max 0.40 | Max 0.40 | Max 0.030 | Max 0.030 | ||

| W14Cr4VMnRE | 0.80-0.90 | 13.2-15.0 | Max 0.30 | 3.50-4.00 | 1.40-1.70 | – | Max 0.50 | 0.35-0.55 | Max 0.030 | Max 0.030 | RE:0.07 | |

| W12Cr4V4Mo | 1.20-1.40 | 11.5-13.0 | 0.90-1.20 | 3.80-4.40 | 3.80-4.40 | – | Max 0.40 | Max 0.40 | Max 0.030 | Max 0.030 | ||

| W6Mo5Cr4V3 | M3(classa) | 1.00-1.10 | 5.00-6.75 | 4.75-6.75 | 3.75-4.50 | 2.25-2.75 | – | 0.20-0.45 | 0.15-0.40 | Max 0.030 | Max 0.030 | |

| CW6Mo5Cr4V3 | M3(classb) | 1.15-1.25 | 5.00-6.75 | 4.75-6.75 | 3.75-4.50 | 2.75-3.25 | – | 0.20-0.45 | 0.15-0.40 | Max 0.030 | Max 0.030 | |

| W6Mo5Cr4V2Co5 | M35 | 0.80-0.90 | 5.50-6.50 | 4.50-5.50 | 3.75-4.50 | 1.75-2.25 | 4.50-5.50 | 0.20-0.45 | 0.15-0.40 | Max 0.030 | Max 0.030 | |

| W7Mo4Cr4V2Co5 | M41 | 1.05-1.15 | 6.25-7.00 | 3.25-4.75 | 3.75-4.50 | 1.75-2.25 | 4.75-5.75 | 0.15-0.50 | 0.20-0.60 | Max 0.030 | Max 0.030 | |

| W18Cr4VCo5 | T4 T5 T6 |

0.70-0.80 | 17.5-19.0 | 0.40-1.00 | 3.75-4.50 | 0.80-1.20 | 4.25-5.75 | 0.20-0.40 | 0.10-0.40 | Max 0.030 | Max 0.030 | |

| 8W18Cr4V2Co8 | 0.75-0.65 | 17.5-19.0 | 0.50-1.25 | 3.75-5.00 | 1.80-2.40 | 7.00-9.50 | 0.20-0.40 | 0.20-0.40 | Max 0.030 | Max 0.030 | ||

| W12Cr4V5Co5 | T15 | 1.50-1.60 | 11.75-13.00 | Max 1.00 | 3.75-5.00 | 4.50-5.25 | 4.75-5.25 | 0.15-0.40 | 0.15-0.40 | Max 0.030 | Max 0.030 | |

| W6Mo5Cr4V2AI | 1.05-1.20 | 5.50-6.75 | 4.50-5.50 | 8.80-4.40 | 1.75-2.20 | – | 0.20-0.60 | 0.15-0.40 | Max 0.030 | Max 0.030 | AI:0.80-1.20 | |

| W2Mo9Cr4VCo8 | M42 | 1.05-1.15 | 1.15-1.85 | 9.00-10.00 | 3.50-4.25 | 0.95-1.35 | 7.75-8.75 | 0.15-0.65 | 0.15-0.40 | Max 0.030 | Max 0.030 | |

| W7Mo4Cr4V2 | 1.05-1.15 | 6.25-7.00 | 3.25-4.25 | 8.75-4.50 | 1.75-2.25 | 4.75-5.75 | 0.15-0.50 | 0.20-0.60 | Max 0.030 | Max 0.030 | ||

| W10Mo4Cr4V3AI | 1.30-1.45 | 9.00-10.50 | 3.50-4.50 | 3.80-4.50 | 2.70-3.20 | – | Max 0.50 | Max 0.50 | Max 0.030 | Max 0.030 | AI:0.70-1.20 | |

| W6Mo5Cr4V5Si | 1.55-1.65 | 5.50-6.50 | 5.00-6.00 | 8.80-4.40 | 4.20-5.20 | – | 1.00-1.40 | Max 0.40 | Max 0.030 | Max 0.030 | Nb:0.2-0.5 AI:0.3-0.7 |

|

| W12Mo3Cr4V3Co5Si | 1.20-1.30 | 11.50-13.50 | 2.80-3.40 | 3.80-4.40 | 2.80-3.40 | 4.70-5.10 | 0.80-1.20 | Max 0.40 | Max 0.030 | Max 0.030 |

High Speed Steel Main Categories

High speed steel is a kind of complex steel, the carbon content is generally between 0.70~1.65%. Contains more alloy elements, the total amount can reach 10~25%.

It can be divided into:

1 Tungsten high-speed steel (containing 9~18% tungsten);

2 Tungsten-Mo high-speed steel (containing 5~12% tungsten ,2~6% molybdenum);

3 High Molybdenum High Speed Steel (containing 0~2% tungsten ,5~10% molybdenum);

4 Vanadium high-speed steel, according to the vanadium content of the general vanadium content (vanadium 1~2%) and high vanadium content (vanadium 2.5~5%) high-speed steel;

5 Cobalt high speed steel (containing 5~10% cobalt).

According to the use of different high-speed steel can be divided into general type and special use two kinds.

Universal high-speed steel: cutting tools (e.g. bits, taps, saw blades) and precision tools (e.g. hobs, shaper cutters, broaches) mainly used in the manufacture of metal materials with cutting hardness HB≤300. The commonly used steel numbers are W18Cr4V 、W6Mo5Cr4V2.

Special purpose high-speed steel: including cobalt high-speed steel and super-hard high-speed steel (hardness HRC68~70), mainly used for cutting difficult metal (such as superalloy, titanium alloy and high strength steel, etc.) cutting tools, commonly used steel W12Cr4V5Co5、W2Mo9Cr4VCo8.

What is High Speed Steel Equivalent?

| China | US | Japan | Germany |

| W18Cr4V | T1 | SKH2 | 1.3355 |

| W18Cr4VCo5 | T4 | SKH3 | 1.3255 |

| W18Cr4V2Co8 | T5 | SKH4 | 1.3265 |

| W12Cr4V5Co5 | T15 | SKH10 | 1.3202 |

| W6Mo5Cr4V3Co8 | M3:2+Co | SKH40 | 1.3244 |

| W2Mo8Cr4V | M1 | SKH50 | 1.3327 |

| W6Mo5Cr4V2 | M2 | SKH51 | 1.3343 |

| W6Mo5Cr4V3 W6Mo6Cr4V2 |

M3:1 | SKH52 | 1.3350 |

| CW6Mo5Cr4V3 | M3:2 | SKH53 | 1.3344 |

| W6Mo5Cr4V4 | M4 | SKH54 | 1.3351 |

| W2Mo9Cr4V2 | M7 | SKH58 | 1.3348 |

| W6Mo5Cr4V2Co5 | M35 | SKH55 | 1.3243 |

| W6Mo5Cr4V2Co8 | M36 | SKH56 | 1.3294 |

| W2Mo9Cr4VCo8 | M42 | SKH59 | 1.3247 |

| W10Mo4Cr4V3Co10 | M48 | SKH57 | 1.3207 |

What is High Speed Steel Properties?

W18Cr4V

It has great hot hardness.And it is easy to grinding and processing.The quenching superheat sensitivity is small,and the heat resistance is higher than alloy steel.And it also has good toughness and machinability at 600℃. But its carbide is bigger.The strength and toughness will down by the material size increases.Only suited to make normal knife tools.It is not a good material to make large size knife tools and thin blades.It is widely to make all kinds of cutting tools with medium hardness.Such as turning tools,milling cutters, broaching tools and etc.And also be made cold work mold bases,the fittings that work at high temperatures environment and etc.

W18Cr4V-Co5It is cobalt high speed steel.It has good hardness in the high temperature.The wear resistance and quenching hardness are high.The hardness of the surface can reach 64-66HRC.It is great material of all kinds of cutting tools for high-speed cutting with high hardness.Such as hobbing cutter,turning tools,milling cutters and the processing cutting tools for the automatic machine tool.

W18Cr4V2-Co8

It also is cobalt high speed steel.Its hot hardness and wear resistance are all better than W18Cr4VCo5.But the toughness is lower.Quenching hardness is reached to 64-66HRC (the hardness of space). People always use it to make hobbing cutter,turning tools,milling cutters and etc.

W12Cr4V5-Co5

It is cobalt high speed steel with a high content of carbon and vanadium.It has great wear resistance and hardness.And it has good temper resistance and hot hardness.So its service life is longer than other high speed steel.It is the perfect choice for the material which is difficult to processing.Such as high strength steel,medium strength steel,cold rolled steel,alloy steel and etc.It also is usually used to make cutter gear,threading tool and cold work mold base.But is not able to use to make complex cutting tools which with high degree of accuracy.

W6Mo5Cr4-V2

It has great hot hardness and toughness.After quenching,the hardness of the surface can up to 64-66HRC.It is molybdenum high speed steel with low tungsten content.The cost is lower than W18Cr4V.And it is one of the most popular of high speed steel.It is usually used to make drill bit,screw tap,screw die and etc.

CW6Mo5-Cr4V2After quenching,its hardness of the surface,thermal stability,wear resistance are all better than W6Mo5Cr4-V2.But its strength and impact ductility is lower than W6Mo5Cr4-V2.People usually use it to make the knife with high machinability.Such as broaching tool,reamer bit and etc.

W6Mo5Cr4-V3

Its carbide is little and distributes rectangularly.Also has good plasticity and toughness.And the wear resistance is better than W6M05Cr4V2.But the grindability is bad and easy to oxidative decarburization.It is not a good choice for making high-precision complex cutting tools.It can be used to make all kinds of generic cutting tools.Such as turning tool,milling cutter and etc.

CW6Mo5-Cr4V3It is Mo-series high speed steel with high carbon and high vanadium.On the base of W6M05Cr4-V3to improve its average carbon content from 1.05%to 1.20%. And also improve the vanadium content to make its wear resistance get better.

High Speed Tool Steel Grades Equivalent Table

High speed tool steel has high hardness, strength and wear resistance.But the difference between the carbon steel and high speed tool steel is that high speed tool steel has high red hardness.So is good material for high speed cutting.As below, I will show you all the information of High Speed Tool Steel grade equivalents table for American ASTM, UNS, to GB, ISO, Europe, Germany, France, and Japan.And as a leader steel supplier in China, if you need the material as below, please kindly contact us.

| GB | ISO | ASTM | UNS | JIS | DIN | BS | NF |

| W18Cr4V | HS18-0-1 | T1 | T12001 | SKH2 | S18-0-1-B18 | BT1 | HS18-0-1 Z80WCV18-04-01 Z80WCN18-04-01 |

| W18Cr4VCo5 | HS18-1-1-5 | T4 T5 T6 |

T12004 T12005 T12006 |

SKH3 SKH4A SKH4B |

S18-1-2-5 S18-1-2-10 S18-1-2-15 |

BT4 BT5 BT6 |

HS18-1-1-5 Z80WKCV18-05-04-01 Z85WK18-10 |

| W18Cr4V2Co8 | HS18-0-1-10 | T5 | T12005 | SKH40 | S18-1-2-10 | BT5 | HS18-0-2-9 Z80WKCV18-05-04-02 |

| W12Cr4V5Co5 | HS12-1-5-5 | T15 | T12015 | SKH10 | S12-1-4-5 S12-1-5-5 |

BT15 | Z160WK12-05-05-04 HS12-1-5-5 |

| W6Mo5Cr4V2 | HS6-5-2 | M2(Regular C) | T11302 T11313 |

SKH51 SKH59 |

S6-5-2 SC6-5-2 |

BM2 | HS6-5-2 Z85WDCV06-05-04-02 Z90WDCV06-05-04-02 |

| CW6Mo5Cr4V2 | — | M2(high C) | T11302 | — | SC6-5-2 | — | — |

| W6Mo5Cr4V3 | HS6-5-3 | M2(classa) | T11313 | SKH52 | S6-5-3 | — | Z120WDCV06-05-04-03 |

| CW6Mo5Cr4V3 | HS6-5-3 | M2(classb) | T11323 | SKH53 | S6-5-3 | — | HS6-5-3 |

| W2Mo9Cr4V2 | HS2-9-2 | M7 | T11307 | SKH58 | S2-9-2 | — | HS2-9-2 Z100DCWV09-04-02-02 |

| W6Mo5Cr4V2Co5 | HS6-5-2-5 | M35 | — | SKH55 | S6-5-2-5 | — | HS6-5-2-5 Z85WDKCV06-05-05-04-02 |

| W7Mo4Cr4V2Co5 | HS7-4-2-5 | M41 | T11341 | — | S7-4-2-5 | — | HS7-4-2-5 Z110WKCDV07-05-04-04-02 |

| W2Mo9Cr4VCo8 | HS2-9-1-8 | M42 | T11342 | SKH59 | S2-10-1-8 | BM42 | HS2-9-1-8 Z110WKCDV09-08-04-02-01 |

What is High Speed Tool Steel Applications?

The carbon content of high speed tool steel is on the range for 0.70%–1.65%. The alloy content is on the range of 10%–20%. That improves the hardness,hardenability,wear resistance and hot hardness dramatically.There are all kinds of alloy carbide inside,it still has a high hardness at the 600℃high temperature.They are suitable for making cutting tools with high cutting speed requirement.And also good for the big size or small size cutting tools that have high requirement for high wear resistance.And it is used to make the molds, roll and machine fittings with high wear resistance requirement.

According to the different alloy elements,high speed tool steel can be divided into tungsten high speed steel,molybdenum high speed steel,cobalt high speed steel,high-vanadium high speed steel and etc.So different grade tool steel of it has different applications.As below,I will show the details for you.

What is High Speed Steel Used for?

- GB W18Cr4V /ASTM T1/JIS SKH2

GB W18Cr4V is equivalent to ISO HS18-0-1,ASTM T1,UNS T12001,JIS SKH2,DIN S18-0-1-B18.This steel belongs to the tungsten high speed steel,it has higher toughness,hot hardness and high-temperature hardness.It’s not easy to get overheated during the quenching,but the machinability is good.The disadvantages for it are bad thermoplasticity and toughness.

It is suitable for the cutting tools with high speed cutting,including lathe tool,drill bit,milling cutter and etc.And also can be used to make screw tap,wire-drawing die,saw web and etc.

- GB W18Cr4V2Co8/ASTM T5/JIS SKH40

GB W18Cr4V2Co8steel is equivalent to ISO HS18-0-1-10,ASTM T5,UNS T12005,JIS SKH40,DIN S18-1-2-10steel.It also is the tungsten high speed steel,but it has the cobalt element.Its hot hardness,high-temperature hardness and wear resistance are better than GB W18Cr4V.But the toughness gets down.

It is a good choice for making the tools with the complex conditions for the working,such as lathe tool,willing cutter,hob and more.

- GB W12Cr4V5Co5/ASTM T15/JIS SKH10

The equivalent steel grades for GB W12Cr4V5Co5are ISO HS12-1-5-5,ASTM T15,UNS T12015,JIS SKH10,DIN S12-1-4-5.It is the tungsten high speed steel with cobalt and high vanadium.It has great hardness and wear resistance.But the machinability,strength and toughness are bad.It is not a good choice to make complex cutting tools with high speed cutting.

It is suitable for making cutting tools with special wear resistance requirements.Such as the thread chasers,drawknife and etc.And it also can be used to make the cold-work dies.

- GB W6Mo5Cr4V2/ASTM M2(Regular C)/JISSKH51SKH59

GB W6Mo5Cr4V2steel is equivalent to ISO HS6-5-2,ASTM M2(Regular C), JISSKH51SKH59, DIN S6-5-2. This steel has good hardness and hardship. After inquiry, the surface hardness can be 64 HRC -66 HRC. It is one of the most popular high speed tool steel.

It is a good material for the drill bit,screw tap,milling cutter,cold work mold and etc.

- GB CW6Mo5Cr4V2/ASTM M2(High C)/DIN SC6-5-2

GB CW6Mo5Cr4V2is equivalent to ASTM M2(High C), UNS T11302, DIN SC6-5-2.After the query, its wear resistance, high-temperature hardness, thermal stability, surface hardness all better than W6Mo5Cr4V2. But the strength and impact althoughness are got lower.

It was be used to make the cutting tools with high machinability.Such as the broach,reamer,hob and etc.

- GB W2Mo9Cr4V2/ASTM M7/JIS SKH58

GB W2Mo9Cr4V2is equivalent to ISO HS2-9-2,ASTM M7,UNS T11307,JIS SKH58,DIN S2-9-2.It has good wear resistance,hot hardness and toughness.And the density is small,the machinability is good,the performance for cutting the common material is great.

And it is suitable for milling cutter,screw tap,saw blade,lathe tool,broach,cold-punching mold and etc.

- GB W6Mo5Cr4V2Co5/ASTM M35/JIS SKH55

GB W6Mo5Cr4V2Co5is equivalent to HS6-5-2-5,ASTM M35,JIS SKH55,DIN S6-5-2-5.It is the cobalt high speed steel.It has good wear resistance,machinability,hot hardness and high-temperature hardness.But the strength and impact toughness is not high.

It can be used to make all kinds of cutting tools,such as the punches,milling cutter and etc.

- GB W7Mo4Cr4V2Co5/ASTM M41

GB W7Mo4Cr4V2Co5is equivalent to ISO HS7-4-2-5,ASTM M41,UNS T11341,DIN S7-4-2-5.At the base of the W6Mo5Cr4V2Co5to add 5%cobalt content.And increase the carbon content and adjust the content of tungsten and molybdenum.Which help the steel to get higher red hardness and high temperature hardness.And improve the wear resistance.Its machinability is good,but the strength and impact toughness are lower.

It also be used for gear cutter,milling cutter,punches and more.

- GB W2Mo9Cr4VCo8/ASTM M42/JIS SKH59

GB W2Mo9Cr4VCo8is equivalent to ISO HS2-9-1-8,ASTM M42,UNS T11342,JIS SKH59,DIN S2-10-1-8.It is high carbon high cobalt high speed steel.It has high hot hardness,high-temperature hardness and machinability.

This steel is suitable for all kinds of high precision complex cutting tools.Such as the forming milling cutter,individual drill bit,lathe tool and etc.

What is High Speed Steel Main Performance?

Also known as wind steel or front steel, also known as white steel. It means that even cooling in air can harden and sharp when quenched. It is a complex alloy steel, containing tungsten, molybdenum, chromium, vanadium, cobalt and other carbide forming elements.Alloy elements total up to 10~25% or so. which can still maintain high hardness under the condition of high heat produced by high speed cutting (about 500℃) and can HRC be above 60. And this is the most important characteristic of high-speed steel —— red hardness. The hardness of carbon tool steel is very high at room temperature after quenching and tempering at low temperature, but when the temperature is higher than 200℃, the hardness decreases sharply, and the hardness of carbon tool steel decreases to a similar degree to that of annealing at 500℃. This limits cutting tools. The high-speed steel can be used to manufacture cutting tools because of its good red hardness, which makes up for the fatal shortcoming of carbon tool steel.

High-speed steel generally do not do tensile strength test, but mainly metallographic, hardness test.

After proper heat treatment, the hardness of tungsten and molybdenum high speed steel is above 63, and that of cobalt high speed steel is above 65. The acid-impregnated low-power steel tissue must not have visible shrinkage holes, skin. The center is loose, generally loose should be less than 1 grade.

The contents of metallographic examination mainly include decarburization layer, microstructure and carbide inhomogeneity.

- high-speed steel should not have obvious decarbonization. The microstructure must not exist in fish bone eutectic Lainite.

Carbide inhomogeneity in 2. high speed steel has the greatest influence on the quality, and the metallurgical and mechanical departments attach great importance to the level of carbide inhomogeneity. According to the different uses of steel, different grade requirements for carbide inhomogeneity can be put forward, usually less than grade 3.

- high-speed steel is used to make cutting tools, in addition to its high hardness, high wear resistance and sufficient toughness, there is also an important factor is red hardness. (Red hardness refers to the ability of the cutting edge to resist softening in a red-hot state when cutting at high speed. )

One way to measure red hardness is to heat the steel to 580~650℃, hold it for 1 hour, then cool it, and then measure its hardness after 4 times. The quenching temperature of high speed steel is generally close to the melting point of steel, such as 1210~1240℃ of tungsten high speed steel and 1180~1210℃ of high molybdenum high speed steel. Quenching generally need to be between 540~560℃ tempering 3 times. Increasing the quenching temperature can increase the red hardness of steel. In order to improve the service life of high speed steel tool, the surface can be strengthened, such as low temperature cyanide, nitriding, sulfur nitriding and so on.

What is the difference between tool steel and high speed steel?

Tool steel refers to a variety of carbon and alloy steels that are particularly when used for cutting and drilling. … Tool steel is generally divided into carbon tool steel, alloy tool steel and high-speed tool steel. High Speed Steel is a high carbon tool steel, containing lots of tungsten and cobalt and is rich in molybdenum, tungsten and vanadium.

High Speed Steel Packaging & Inspection

Packaging

Bind delivery, tied with wire, and marked with furnace number, specifications, etc. But cold-rolled steel should also be coated with rust-proof oil, wrapped with moisture-proof paper, Yinliang steel should also be packed.

Inspection

The unevenness of carbide in high speed steel is related to the corrosion time of the sample. It is often ignored that the standard only suggests that corrosion should not be too corroded properly. Practice has proved that if the corrosion occurs, the carbides will be dyed black, showing the false phase of uneven improvement, and the high speed steel with poor quality may be misjudged as high quality steel, which is particularly important.

Page Contents

- High Speed Steel – The Comprehensive FAQ Guide

- What is High Speed Steel or HSS?

- What is High Speed Steel Made Of?

- Advantages and Pros of Using High Speed Steel

- High Speed Steel Disadvantages

- What is the Melting Point of HSS?

- Different Types of High Speed Steel

- What Do The Numbers After the Letters of High Speed Steel Grade Mean?

- What is M2 High Speed Steel?

- High Speed Steel (HSS) vs. Tungsten Carbide Steel

- Does HSS Steel Rust?

- What are the Applications of High Speed Steel?

- High Speed Steel For Sale

- HSS Prices and Rates

- Where Should I Purchase High Speed Steel?

- High Speed Steel Buying Guide

- What is High Speed Steel?

- How to produce high speed steel?

- High Speed Steel Specification and Appearance

- What is High Speed Steel Chemical Composition?

- High Speed Steel Main Categories

- What is High Speed Steel Equivalent?

- What is High Speed Steel Properties?

- High Speed Tool Steel Grades Equivalent Table

- What is High Speed Tool Steel Applications?

- What is High Speed Steel Used for?

- What is High Speed Steel Main Performance?

- What is the difference between tool steel and high speed steel?

- High Speed Steel Packaging & Inspection

- High Speed Steel Grade List

High Speed Steel Grade List

| AISI/ASTM | Werkstoff | EN/DIN | BS | JIS/KS |

| M2 | 1.3343 | HS6-5-2 | BM2 | SKH9 / SKH51 |

| M3 | 1.3344 | HS6-5-3 | – | SKH53 |

| M7 | 1.3348 | HS2-9-2 | – | SKH58 |

| M35 | 1.3243 | HS6-5-2-5 | BM35 | SKH55 |

| M42 | 1.3247 | HS2-9-1-8 | BM42 | SKH59 |

| T1 | 1.3355 | HS18-0-1 | BT1 | SKH2 |

| T4 | 1.3255 | S18-1-2-5 | BT4 | SKH3 |

| T5 | 1.3265 | S18-1-2-10 | BT5 | SKH4 |

| T15 | 1.3202 | S12-1-4-5 | BT15 | SKH10 |