DIN 1.2311 Tool Steel

DIN 1.2311 Tool Steel is a low alloyed steel with 2.0% Cr ,0.15%Mo as per DIN standard.As plastic mold tool steel, it has good toughness,wear resistance after Nitriding. It is mostly used in the hardened and tempered condition with hardness 285-320 HBW.Typical application for this steel are:For large injection and compression molds, Blow molds,die holder, backers and Structural components, shafts,etc.

DIN 1.2311 steel Supply Form & Size

| Form of Supply | Size(mm) | Length(mm) |

| Round bar | Φ6-Φ1,000 | 3,000-10,000 |

| Square bar | 100×100-600×600 | 3,000-6,000 |

| Plate/Sheet | Thickness :20-400 Width:80-1,000 |

2,000-6,000 |

| Flat bar/Blcoks | Thickness :120-800 Width:120-1,500 |

2,000-6,000 |

DIN 1.2311 steel Surface Finish&Tolerance

| Surface Finish | Black-Forged | Black-Rolled | Turned | Grinding | Polished | Peeled | Cold Drawn |

| Tolerance | (0,+5mm) | (0,+1mm) | (0,+3mm) | Best h9 | Best h11 | Best H11 | Best H11 |

Chemical Composition per EN ISO 4957 (Cold Work Tool Steel)

| GRADE | NUMBER | C | Si | Mn | P | S | Cr | Mo |

| 40CrMnMo7 | 1.2311 | 0.35-0.45 | 0.20-0.40 | 1.30-1.60 | ≤ 0.030 | ≤ 0.030 | 1.80-2.10 | 0.15-0.25 |

Related Specifications

ASTM:P20

DIN:40CrMnMo7

AFNOR:40CMD8

GB:3Cr2Mo

Heat Treatment & Mechanical Property

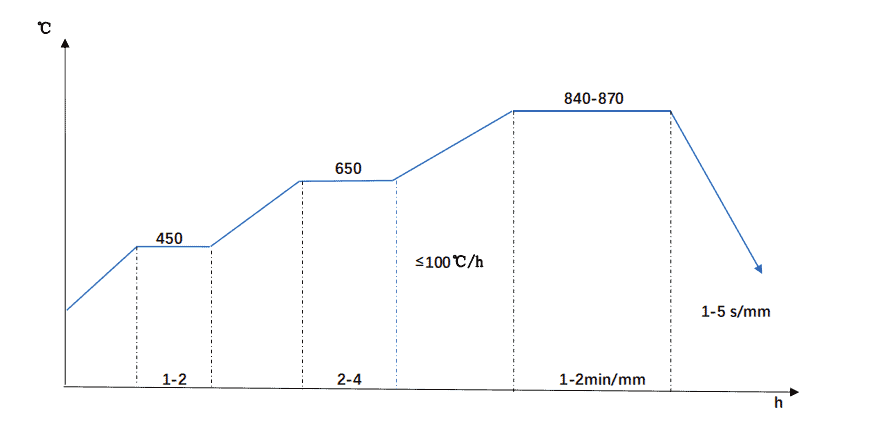

Quenching Details

1.Quench temperature:840-870℃

2.Three steps for heating,hold suitable time for the steel to be thoroughly heated.

3.Oil or water quench.

4.Tempering immediately after quenched

DIN 1.2311 Quenching Diagram

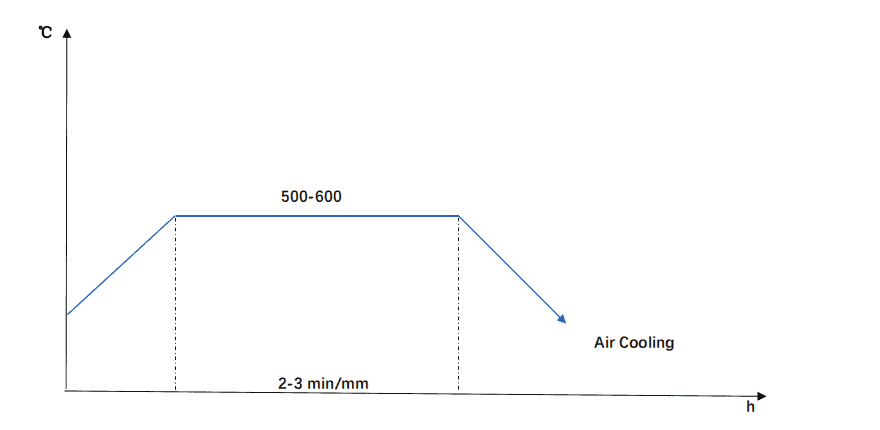

Tempering Details

1.Temper temperature:500-600℃

2.Air cooling.

DIN 1.2311 Tempering Diagram

| Size mm | Tensile,Mpa | Yield,Mpa | Charpy Impact,J | Hardness,HB |

| 355*500 | 1000 | 900 | 20 | 290-327 |

| 400*450 | 1100 | 910 | 25 | 302-330 |

| 500*1000 | 1100 | 935 | 24 | 292-330 |

DIN 1.2311 Hardness Vs Tempering temperature

| Tempering Temperature,℃ | 200 | 300 | 400 | 500 | 600 | 700 |

| Hardness,HRC | 50 | 48 | 46 | 42 | 36 | 28 |

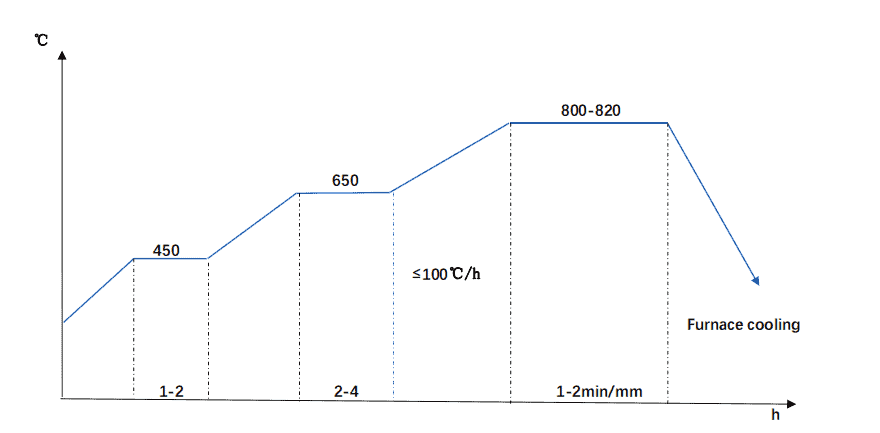

Annealing Details

1.Annealing temperature:800-820℃

2.Enough soaking time for the steel heating

3.Cooling in the furnace.

4.Max hardness:229HB

DIN 1.2311 Annealing Diagram

Comprehensive Guide to DIN 1.2311 Tool Steel

DIN 1.2311 is a widely used low-alloy tool steel known for its excellent machinability, good wear resistance, and consistent hardness across large sections. This guide outlines its properties, processing, and applications to assist engineers and manufacturers in making informed decisions.

1. Introduction to DIN 1.2311

- Definition:

DIN 1.2311 is a pre-hardened low-alloy tool steel with superior machinability, moderate strength, and excellent polishability. It is commonly used for molds, dies, and other tooling components. - Common Uses:

Primarily used in plastic injection molds, die-casting dies, and various mold-making components where dimensional stability and durability are critical. - Equivalent Grades:

- AISI P20 (USA)

- 40CrMnMo7 (Germany)

- AFNOR 40CMD8 (France)

2. Chemical Composition

DIN 1.2311’s chemical composition ensures its strength, wear resistance, and durability:

| Element | Percentage (%) |

|---|---|

| Carbon (C) | 0.35 – 0.45 |

| Silicon (Si) | 0.20 – 0.40 |

| Manganese (Mn) | 1.30 – 1.60 |

| Phosphorus (P) | ≤ 0.03 |

| Sulfur (S) | ≤ 0.03 |

| Chromium (Cr) | 1.80 – 2.10 |

| Molybdenum (Mo) | 0.15 – 0.25 |

This balanced composition provides the material with its machinability, polishability, and toughness.

3. Physical Properties

DIN 1.2311 exhibits the following physical characteristics:

- Density: Approximately 7.84 g/cm³

- Coefficient of Thermal Expansion:

- 12.7 × 10⁻⁶ m/m·K at 20–100°C

- Thermal Conductivity:

- 32 W/m·K at 23°C

These properties make it suitable for molds and dies requiring stability under thermal and mechanical stresses.

4. Mechanical Properties

DIN 1.2311’s mechanical properties in its pre-hardened condition are as follows:

| Property | Metric Values |

|---|---|

| Hardness (Brinell) | ~300 HB |

| Hardness (Rockwell C) | ~30 HRC |

| Tensile Strength (Ultimate) | 965 – 1100 MPa |

| Yield Strength | 827 – 910 MPa |

| Elongation at Break | ~20% |

| Charpy Impact (V-Notch) | 20 – 25 J |

This combination of properties ensures toughness and wear resistance while allowing for efficient machining.

5. Heat Treatment

DIN 1.2311 is supplied in a pre-hardened state, but further heat treatment can enhance its properties for specific applications.

- Annealing:

- Temperature: 710–740°C

- Cooling: Furnace cooling to ensure uniform softening.

- Max Hardness: 235 HB

- Hardening:

- Temperature: 850–880°C

- Quenching Medium: Oil or salt bath for rapid cooling.

- Hardness After Quenching: Up to 52 HRC

- Tempering:

- Temper immediately after quenching to avoid stress build-up.

- Tempering Temperatures and Corresponding Hardness:

- 100°C: 52 HRC

- 200°C: 50 HRC

- Up to 600°C: Hardness decreases progressively with temperature.

These processes allow DIN 1.2311 to meet specific hardness and toughness requirements in demanding applications.

6. Applications

DIN 1.2311 is extensively used in the mold-making and tooling industry due to its favorable properties:

- Plastic Injection Molds: Suitable for producing high-precision and high-volume plastic components.

- Die-Casting Dies: Ideal for zinc and aluminum casting due to its toughness and wear resistance.

- Die Holders and Backers: Ensures stability and uniform hardness in supporting structures.

- Structural Components in Mold Making: Provides dimensional stability and wear resistance in molds.

- Shoe Blocks and Pressure Casting Molds: Suitable for molds exposed to high pressures during casting.

7. Supply Forms

DIN 1.2311 is available in various forms to suit different manufacturing needs:

- Round Bars: Diameter ranges from 6 mm to 1000 mm

- Square Bars

- Plates and Sheets: Thickness ranges from 20 mm to 400 mm

- Flat Bars and Blocks

Its availability in multiple sizes ensures versatility in mold and tooling applications.

8. Conclusion

DIN 1.2311 tool steel is a cornerstone material in mold manufacturing, offering a balance of machinability, polishability, and wear resistance. Its pre-hardened state eliminates the need for extensive heat treatment, reducing production time and costs.

Whether used for plastic injection molds, die-casting dies, or structural mold components, DIN 1.2311 provides consistent and reliable performance. This guide highlights its properties, processing techniques, and applications to support engineers and manufacturers in selecting the most suitable materials for their projects.