DIN 1.0501 Steel

As a high-quality carbon structural steel, DIN 1.0501 is defined as an unalloyed steel with a moderate carbon content of 0.35% as per European standards.

DIN 1.0501 steel has appropriate strength, good plasticity and good process performance. Compared with C22 steel, the welding performance is slightly worse, but still acceptable.Normally, C35 steel is used in normalized and quenched and tempered condition.

DIN 1.0501 steel is widely used in the manufacture of various forgings and hot-pressed parts, cold-drawn and upsetting steels, seamless steel pipes, parts in machinery manufacturing, such as crankshafts, rotating shafts, shaft pins, levers, connecting rods, beams, sleeves, wheels Rings, washers, screws, nuts, etc.

DIN 1.0501 STEEL CHEMICAL COMPOSITION

| Standard | Grade | C | Si | Mn | P | S | Cr | Mo | Ni |

| EN10083 | C35/1.0501 | 0.32-0.39 | ≤0.4 | 0.50-0.80 | ≤0.045 | ≤0.045 | ≤ 0.4 | ≤ 0.1 | ≤ 0.4 |

| EN10250 | |||||||||

| DIN 17200 | CK35/1.1181 | 0.32-0.39 | ≤0.4 | 0.50-0.80 | ≤0.035 | ≤0.03 | – | – | – |

| SEW550 | CK35/1.1181 | 0.32-0.39 | ≤0.35 | 0.50-0.80 | ≤0.035 | ≤0.035 | – | – | – |

DIN 1.0501 STEEL RELATED STANDARD & EQUIVALENT GRADE

China | GB 3077:35

USA | ASTM A29:1035

Japan | JIS G4051:S35C

UK |BS970:080M36

France | NFA 33-101:AF55-C35

DIN 1.0501 STEEL PHYSICAL PROPERTY

| Density, g/cm3 | 7.87 |

| Melting point,℃ | 1395 |

| Specific heat capacity,(0~100℃),J/(kg.k) | 482 |

| Linear expansion coefficient,10^-6/k | 12.45(0-100℃) |

| Poisson’s ratio | 0.29 |

| Elastic Modulus,Mpa | 212213 |

| Shear modulus,Mpa | 82080 |

| Thermal conductivity,W/(m.K) | 46(100℃) |

DIN 1.0501 STEEL FORGING

- Initial Forging Temperature:1200℃

- Final Forging Temperature:800℃

- Forging Ratio:above 4:1

- Post-Forging Treatment:C35 steel should be slowly cooling after forged.

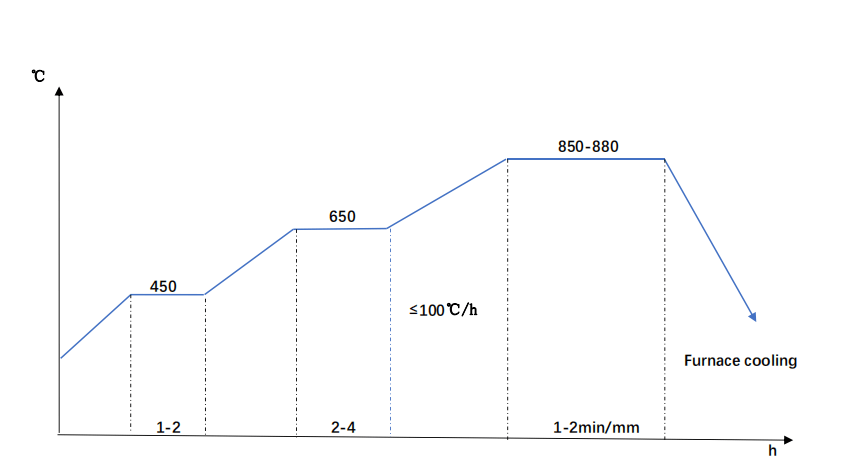

DIN 1.0501 STEEL HEAT TREATMENT

Critical Temperature for Heat Treatment of DIN 1.0501 Steel

- Ac1:724℃

- Ac3:802℃

- Ar1:680℃

- Ar3:774℃

Temperature Selection for Conventional Heat treatment for DIN 1.0501 Steel

- Annealing:850 – 880°C,Cooling in furnace,hardness below 187 HBW

- Normalizing:860-900°C,Cooling in air,hardness 137-197 HBW

DIN 1.0501 Steel Normalizing Diagram

- Quenching:840-880°C,Medium:Water,Oil

- Tempering:550-660°C

DIN 1.0501 Steel Mechanical Property with Quenched and Tempered Condition

| Tensile Strength Mpa |

Yield Strength Mpa |

Elongation % |

Reduction of Area % |

Impact Charpy-V J |

| ≥530 | ≥315 | ≥20 | ≥45 | ≥55 |

DIN 1.0501 Steel Tempering Temperature Vs Hardness

| Grade | Quenching | Tempering Temperature,ºC | |||||||

| Temperature,ºC | Hardness,HRC | 150ºC | 200ºC | 300ºC | 400ºC | 500ºC | 550ºC | 600ºC | |

| DIN 1.0501 | 860ºC | 49-50 | 49 | 48 | 43 | 35 | 26 | 22 | 20 |

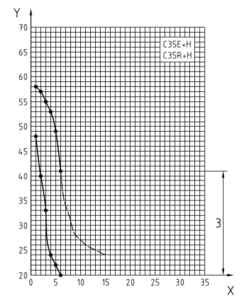

Jominy Quenching Test Curve For C35E Steel

Quenching at 870°C

X:Distance from quenched end,in mm

Y:Hardness,HRC

3: H level

| HRC-mm | Type | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 13 | 15 |

| MIN | +H | 58 | 57 | 55 | 53 | 49 | 41 | 34 | 31 | 28 | 27 | 26 | 25 | 24 |

| MAX | 48 | 40 | 33 | 24 | 22 | 20 | – | – | – | – | – | – | – |

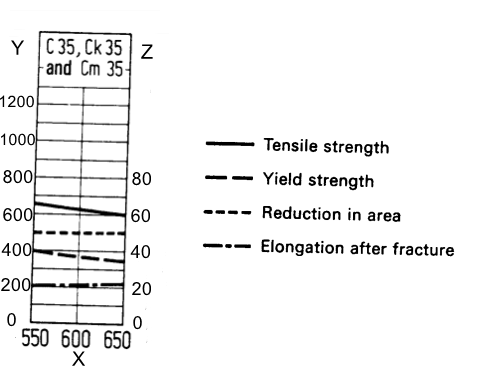

Guideline value Curve for DIN 1.0501 Steel Mechanical Property

X:Tempering temperature,oC

Y:Tensile and Yield Strength,Mpa

Z:Elongation and Reduction in area,%

WHAT WE SUPPLY FOR DIN 1.0501 STEEL

Hot Forged Round bar:Φ80-Φ1000mm

Hot Rolled Round bar:Φ16-Φ350mm

Hot Forged Square bar: Max Thickness:500mm

Flat bar/Blcoks:Thickness :120-800mm ,Width:120-1500mm

| Surface Finish | Black-Forged | Black-Rolled | Turned | Grinding | Polished | Peeled | Cold Drawn |

| Tolerance | (0,+5mm) | (0,+1mm) | (0,+3mm) | Best h9 | Best h11 | Best H11 | Best H11 |