AISI P20 Tool Steel

AISI P20 tool steel Manufacturer and Exporter,supplied with round,square,flat,block,and shaft etc.AISI P20 is a Cr-Mo alloyed steel as per ASTM A681.It is generally supplied in the hardened and tempered condition with hardness 285-340 HBW.Compared with P20+S(1.2312), it has good polishing and texturing properties,good machinability,and uniform hardness.

AISI P20 Tool Steel Supply Form & Size & Tolerance

| Supply Form | Size(mm) | Process | Tolerance | |

| Round | Φ6-Φ100 | Cold Drawn | Bright/Black | Best H11 |

| Φ16-Φ350 | Hot Rolled | Black | -0/+1mm | |

| Peeled/ground | Best H11 | |||

| Φ90-Φ1000 | Hot Forged | Black | -0/+5mm | |

| Rough Turned | -0/+3mm | |||

| Flat/Square/Block | Thickness :120-800 | Hot Forged | Black | -0/+8mm |

| Width:120-1500 | Rough Machined | -0/+3mm | ||

Remark:Tolerance can be customized as per requests

AISI P20 Tool Steel Chemical Composition per ASTM A681

| GRADE | C | Si | Mn | P | S | Cr | Mo |

| P20 | 0.28-0.40 | 0.20-0.80 | 0.60-1.00 | ≤ 0.030 | ≤ 0.030 | 1.40-2.00 | 0.30-0.55 |

AISI P20 Tool Steel Physical Property

| Temperature | 20°C | 200°C |

| Density,kg/m3 | 7800 | 7750 |

| Modulus of elasticity,N/mm2 | 250000 | 200000 |

| Coefficient of thermal expansion,per °C from 20°C | — | 12.7 x 10 ^–6 |

| Thermal conductivity,W/mk | 29 | 29.5 |

| Specific heat,J/kg °C | 460 | — |

AISI P20 Tool Steel Mechanical Property

| Testing temperature | 20°C | 200°C |

| Tensile strength Rm,N/mm2 | 1020 | 930 |

| Yield strength Rp 0.2,N/mm2 | 900 | 800 |

| Compressive yield strength Rc 0.2,N/mm2 | 850-1000 | |

| Elongation ,% | 20 | — |

| Charpy-v impact,J | 27 | — |

AISI P20 Tool Steel Forging

Heat AISI P20 to the temperature 700 oC ,hold for suitable time,then heat the temperature uniformly to 900 oC – 1100 oC.Forging below 870°C is not recommended for P20. Cooling in sand after forged.

AISI P20 Tool Steel Stress Relieving

After rough machining ,P20 should be heated through to500- 550°C, holding time 2 hours. Cool slowly in the furnace to room temperature.

AISI P20 Tool Steel Annealing

Heat P20 in a protective atmosphere (preferably a controlled atmosphere furnace) to 720-750°C,and hold for one hour per inch of thickness. Cool in the furnace at 10°Ccper hour to 600°C,Then air-cool to room temperature.The resulting hardness Is Brinell 235 max.

AISI P20 Tool Steel Hardening

Preheating temperature: 500–600°C

Austenitizing temperature: 880°C.

The steel should be heated through to the austenitizing temperature and hold at temperature for 30 minutes. Protect the tool against decarburization and oxidation during the hardening process.

Quenching Media

• High speed gas/circulating atmosphere. (Only suitable for small dimensions)

• Oil (Warm oil (65-80°C))

• Martempering bath 300°C, max. 4 minutes,then air cool

Note: Temper immediately when tool reaches 50–70°C.

AISI P20 Tool Steel Tempering

Choose the tempering temperature according to the hardness required by reference to the tempering graph. Temper twice with intermediate cooling to room temperature. Lowest tempering temperature 180°Cfor small inserts, but preferred minimum is 250°C, unless material is to be nitride or nitrocarburized later. Holding time at temperature minimum 2 hours.

| Tempering,°C | 100 | 200 | 300 | 400 | 450 | 500 | 550 | 600 |

| HRC | 56 | 54 | 51 | 47 | 44 | 42 | 39 | 36 |

| Rm,N/mm2 | 2050 | 1910 | 1730 | 1530 | 1400 | 1330 | 1230 | 1140 |

AISI P20 Tool Steel Application

AISI P20 tool steels are used for low temperature applications that include injection molds and die casting dies. Typical application are:

For large injection and compression molds

• Extrusion dies for thermoplastics

• Blow molds

• High strength holders, plates and bolsters

• Forming tools, press-brake dies (possibly flame hardened or nitrided)

• Aluminum die casting prototype dies

• Zinc die casting dies

• Long run die shoes

• Structural components, shafts

AISI P20 Tool Steel – The Comprehensive FAQ Guide

AISI P20 tool steels are part of the most common and the most sought after types of tool steels.

In this guide, we’ll not only help you be educated with what AISI P20 tool steel is, you will also learn some of its most common applications, as well as how you can work with the best AISI P20 tool steel manufacturer.

What is AISI P20 Tool Steel?

To understand what AISI P20 tool steel is, you first have to understand the components and the composites of P20.

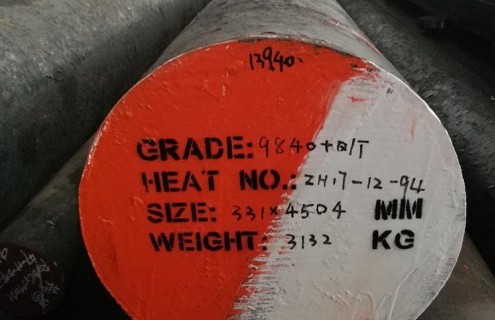

Example of what an AISI P20 tool steel looks like

AISI P20 is a type of chromium molybdenum steel that has specifically been made to be used for plastic molding, die casting, and the like.

Therefore, AISI P20 tool steel is a type of flexible and versatile steel containing low levels of alloys, and is usually distinguished and characterized by moderate strength and toughness levels.

What is Mold Steel?

Mold steel is a type of steel material that’s used in mold manufacturing like hot forging dies, casting molds, cold-punch molds, and the like.

Plastic mold steel example

These types of steels are the primary tool for the machinery and equipment manufacturing industry as they’re easily machinable and weldable.

When it comes to choosing mold steel, a lot of experts recommend none other than P20 tool steel, because of its unique composition and its differential properties.

P20, compared to other types of mold steel, has a melting point of about 2,600 degrees Fahrenheit, or about 1,427 degrees Celsius, which is at the same rate as H13 mold steel.

Moreover, it’s also the type of tool steel that has the Manganese content that can reach an astounding 1%, which reduces the levels of brittleness.

Is P20 Stainless Steel?

Do you know how a type of steel is classified as stainless steel?

In order for a certain steel type to be known and distinguished as stainless steel, the particular steel type needs to have alloying elements and carbon levels that have 1.2% or less, as well as at least 10.5% chromium.

Image of a rolled stainless steel sheet

AISI P20 tool steel’s chemical composition doesn’t even reach 10.5% chromium. In fact, here’s a quick table of stainless steel’s composition.

| Manganese (Mn) | Carbon (C) | Chromium (Cr) | Molybdenum (Mo) | Phosphorus (P) | Silicon (Si) | Sulfur (S) |

| 0.60 to 1.00% | 0.28 to 0.40% | 1.40 to 2.00 % | 0.30 to 0.55% | ≤0.030% | 0.20 to 0.80% | ≤0.030% |

As you can see, the Chromium (Cr) levels of AISI P20 steel don’t even reach 5.00%. Therefore, we can arrive at the conclusion that P20 tool steels could not be classified as stainless steels.

Can AISI P20 Be Hardened?

Yes, as a matter of fact, you can get AISI P20 steels at annealed hardness levels that reach up to Brinell 200. Should a client require a harder, tougher, and a more durable P20 tool steel, it can be carburized or hardened up to a hardness level of 50 to 60 RC.

What is P20 Steel’s Machinability?

You might have wondered, how do experts measure and determine steel’s machinability?

The machinability rating of some steels are determined via quantitatively calculating the weighted average of surface finishes, normal cutting speeds, and the life tool of each material.

NOTE: Materials and steels that have machinability values of 100% and below are harder and more difficult to machine than those that are 100% and higher than this amount.

For P20 tool steels’ machinability, it’s about 80% that of steels that are hardened in water. Therefore, you can easily mold and subject P20 steel into machines and have them worked, formed, and shaped.

What is P20+S Steel?

P20+S steel is a type of plastic mould tool steel. It is P20 steel that contains higher sulfur content, therefore, promotes improved and developed machinability.

Scot Forge: “We’ve Got You Covered!”

The leaders in open-die and rolled-ring forging.

Image of how a P20+S steel looks like

It’s a type or a classification of steel that is not the best if your application requires a smooth and a fine finish because it’s used for steel molding.

Tempering P20+S steel at certain temperatures can have it result to specific hardness levels. For instance, if you temper it at 400 degrees Celsius, it can have an HRD hardness of 46 HRC and tensile strength of 1,480 n/mm2.

Therefore, it’s imperative to know that P20+s steel is different from P20 steel alone.

P20 Tool Steel vs. D2 Steel

We now know that AISI P20 tool steel is a type of chromium-molybdenum steel that’s usually used for plastic molding applications. It’s comprised of low levels of different alloys.

Image of D2 steel being prepared and readied

D2 steel, on the opposite side of the rope, is a type of alloyed steel that has high carbon and high chromium levels. Akin to other types of steel, it has high abrasion and wear capabilities.

Both P20 and D2 steels are machinable in annealed conditions, and both of them can reach up to 55 HRC; P20, though, can only reach 60 HRC if it’s nitrided.

Does P20 Tool Steel Rust

P20 tool steels usually boast of corrosion resistance if it’s required.

Example of rusting mold steels

Naturally, though, P20 steel has a good and high resistance against corrosion.

So, if you’re going to use it for die purposes, you wouldn’t experience any problems or troubles. As a matter of fact, you can also add corrosion and oxidation resistance to its finishing procedure, too.

Overall, though, just like many steel types, AISI P20 steel will rust if not maintained and cared for properly.

P20 Steel vs. 4140 Steel

AISI 4140 steel, just like P20 steel, is a type of chrome-moly steel, with bits of manganese. Many business industries and sectors use this due to its excellent toughness, impact, abrasion, and high wear resistance.

P20 steel, on the other hand, is low carbon mould steel that is typically used and utilized in the plastic molding industry. And while many people think that P20 tool steel’s use is limited that, think again!

AISI P20 tool steel is widely used across different business industries and sectors.

4140 steel is one of the best and the most sought-after types of steel because of the high carbon and chromium content. P20 steel, on the other hand, are considered as tool steels because they’re nitride and/or carburized, which adds up and enhances hardness and toughness.

Pros and Cons of Using P20 Tool Steels

Using AISI P20 tool steels have its benefits and drawbacks. To help you with it further, here are some of the advantages and the disadvantages of utilizing P20 steels:

Pros of Using P20 Steels

- Many engineers and businesses use P20 tool steels because they’re more effective

- They’re tougher, stronger, and more durable than aluminum

- P20 tool steels can resist clamping and injection pressures

- P20 steels are easily weldable and machinable

Cons of Using P20 Steels

Some of the drawbacks of P20 steels include:

- They’re less resistant to chemical corrosion naturally

- PVCs are more corrosive resistant than P20

- Aluminum have longer impact life

P20 Steel Mold Life

Mold life is the classification of a material or a substance’s life cycle of being molded. For instance, a piece of properly formulated stainless steel has a mold life of about 500,000 to 1,000,000 cycles.

The mold service life of P20 tool steels, however, can be up to 500,000 cycles only. This is because they’re usually supplied and distributed as a type of pre-hardened steel, which you can use directly for mold manufacturing.

P20 Steel Price

Unlike what most people believe, P20 tool steels don’t really have a median range of rates and prices. It’s not like other items that you can purchase from hardware stores and shops.

In order for you to find out the price for the P20 steel you’re looking at, the next best thing to do is to approach the supplier or manufacturer and ask for a quotation.

Should you purchase P20 tool steels in retail, expect regular prices. On the other hand, if you’re going to purchase P20 tool steels wholesale, the rates should be lower-than-average.

What are the Typical Uses of AISI P20 Tool Steel?

AISI P20 tool steels are typically used for tooling, die casting, and plastic injection molding activities.

Extrusion die – one of the most common and customary uses of AISI P20 steel

Apart from that, you can also use AISI P20 tool steels for shafts, thermoplastic extrusion dies, press-brake dies, plates and bolsters, and many more!

Whatever industry or sector you are in, you will definitely be able to find use of AISI P20 tool steel! They’re also widely used in car accessories and automotive applications, electronic equipment molds, industrial and structural molds, and many more!

Basic AISI P20 Steel Properties

Some of the properties that are considered to be the simplest and the most basic when it comes to AISI P20 steel include, but are not limited to:

- You can mirror polish P20 tool steels

- Finishing is easier because of less texture

- More often than not, P20 tool steels are pre-hardened at 29 to 33 HRC

- Excellent weldability

- Hardness and toughness is uniform even if supplied in large blocks

- Supplication is usually in its tempered and quenched conditions

These are only some of AISI P20’s properties. There are others and they’re dependent on how you would use and apply them.

What Are the Supply Forms of AISI P20 Tool Steel?

Akin to other types and kinds of steel, you can purchase AISI P20 in many different shapes and forms. These forms include a round bar, a steel plate, a square plate, a sheet, and others.

The most common though would be at the steel plate and the round bar supply form.

How Are P20 Tool Steels Finished?

More often than not, the finishing and the polishing of these AISI P20 tool steels revolve around black surfacing, rough machining, turned and milled, grinded, and the like.

While you can grind it, do not expect it to have a smooth and a flawless finish. It’s not the recommended type of tool steel to use if you’re looking to have a smooth, almost perfect, and a uniform finish.

Where Can You Purchase the Best AISI P20 Tool Steels?

You can find a ton of AISI P20 tool steels in the market today. However, if you want to get the best quality of P20 tool steels, you will never be disappointed in choosing a Chinese supplier/manufacturer.

Most Chinese P20 tool steel manufacturers and suppliers focus on quality because in their competition, their rates and prices are close to one another. Therefore, they’ll only be able to develop and enhance the quality of products as well as customer service, customizability, and many more!

Which AISI P20 Steel Manufacturer Should You Work With?

Here in China, you will never be able to find a trustworthy manufacturer that is as skilled, adept, and as experienced as us here at Waldun Steel.

For years, we’ve been developing the production and the manufacturing procedure of our P20 tool steels. It being one of the most sought-after products that we have, we’ve truly been on the mission to develop and enhance it.

Our company is employed with the best, the most talented, and the most experienced engineers and steel experts who have decades of experience.

Waldun Steel does not have an MoQ, so you shall not be worried about purchasing less. Contact us now here at Waldun Steel and experience world-class quality AISI P20 steel!

Why Trust Waldun Steel?

Waldun Steel has faced a ton of licenses and certifications in the steel sector and industry. We prioritize the needs and wants of all our clients, regardless of their business.

As a company, we never believed in shortcuts – we always wanted to take the longer way but in a sure, better, and a higher quality result.

Talk to us today and never worry about where you can get the best P20 tool steels again! Wherever you are, we’re an email or a call away!

Other Related Steel

Page Contents

- AISI P20 Tool Steel Supply Form & Size & Tolerance

- AISI P20 Tool Steel Chemical Composition per ASTM A681

- AISI P20 Tool Steel Physical Property

- AISI P20 Tool Steel Mechanical Property

- AISI P20 Tool Steel Forging

- AISI P20 Tool Steel Stress Relieving

- AISI P20 Tool Steel Annealing

- AISI P20 Tool Steel Hardening

- AISI P20 Tool Steel Tempering

- AISI P20 Tool Steel Application

- AISI P20 Tool Steel – The Comprehensive FAQ Guide

- What is AISI P20 Tool Steel?

- What is Mold Steel?

- Is P20 Stainless Steel?

- Can AISI P20 Be Hardened?

- What is P20 Steel’s Machinability?

- What is P20+S Steel?

- P20 Tool Steel vs. D2 Steel

- Does P20 Tool Steel Rust

- P20 Steel vs. 4140 Steel

- P20 Steel Mold Life

- P20 Steel Price

- What are the Typical Uses of AISI P20 Tool Steel?

- Basic AISI P20 Steel Properties

- What Are the Supply Forms of AISI P20 Tool Steel?

- How Are P20 Tool Steels Finished?

- Where Can You Purchase the Best AISI P20 Tool Steels?

- Which AISI P20 Steel Manufacturer Should You Work With?

- Why Trust Waldun Steel?

- Other Related Steel