AISI 4140 Steel Bar | 1.7225 | 42CrMo4 | SCM440

Are you looking for AISI 4140 steel bar?

WALDUN is the best AISI 4140 steelbar Manufacturer and Exporter from China. You can get round,square,flat,block,and shaft etc. We are one of the largest manufacturers in China with over 15 years experience. Our products have been exported to many countries all around the world. With our own factory we can provide high quality products at a competitive price!

If you want to buy or wholesale bulk AISI 4140 steel bar in large quantities please contact us now! We will offer you unbeatable prices and service that cannot be matched by other suppliers! Please feel free to send us an inquiry if you need any help or more information about our company or services. We look forward to hearing from you soon!

AISI 4140 steel bar is defined as a low alloy steel which has 1% Cr-Mo as strengthening alloy elements.Compared with AISI 4130, it has a higher carbon content with good balance of strength, toughness ,abrasion and impact resistance and heat treatment capabilities,but poor in weldability characteristics.AISI 4140 is generally supplied in quenched and tempered condition with hardness 28-32HRC. 4140 steel is used to manufacture forgings with higher strength and larger quenched cross-section than 35CrMo steel, such as large gears for locomotive traction, supercharger transmission gears, rear axles, connecting rods and spring clips which are subject to great loads, and also used for oil deep well drill pipe joints and salvage tools below 2000m.

AISI 4140 Steel Bar Supply Form & Size & Tolerance

| Supply Form | Size(mm) | Process | Tolerance | |

| Round | Φ6-Φ100 | Cold Drawn | Bright/Black | Best H11 |

| Φ16-Φ350 | Hot Rolled | Black | -0/+1mm | |

| Peeled/ground | Best H11 | |||

| Φ90-Φ1000 | Hot Forged | Black | -0/+5mm | |

| Rough Turned | -0/+3mm | |||

| Flat/Square/Block | Thickness :120-800 | Hot Forged | Black | -0/+8mm |

| Width:120-1500 | Rough Machined | -0/+3mm | ||

Remark:Tolerance can be customized as per requests

AISI 4140 steel bar Chemical Composition

| Standard | Grade | C | Si | Mn | P | S | Cr | Ni | Mo |

| ASTM A29 | 4140 | 0.38-0.43 | 0.15-0.35 | 0.75-1.00 | ≤ 0.035 | ≤ 0.04 | 0.8-1.1 | – | 0.15-0.25 |

| EN10083 | 42CrMo4 | 0.38-0.45 | ≤ 0.4 | 0.6-0.90 | ≤ 0.025 | ≤ 0.035 | 0.9-1.2 | – | 0.15-0.30 |

| 1.7225 | |||||||||

| JIS G4105 | SCM440 | 0.38-0.43 | 0.15-0.35 | 0.6-0.85 | ≤ 0.035 | ≤ 0.04 | 0.9-1.2 | – | 0.15-0.30 |

| GB 3077 | 42CrMo | 0.38-0.45 | 0.17-0.37 | 0.5-0.80 | ≤ 0.035 | ≤ 0.035 | 0.9-1.2 | – | 0.15-0.25 |

| BS 970 | EN19 | 0.35-0.45 | 0.15-0.35 | 0.5-0.80 | ≤ 0.035 | ≤ 0.035 | 0.9-1.5 | – | 0.2-0.40 |

AISI 4140 steel bar Physical Property

| Density g/cm3 | 7.85 | ||||

| Melting point °C | 1416 | ||||

| Poisson’s ratio | 0.27-0.30 | ||||

| Machinability (AISI 1212 as 100% machinability) | 65% | ||||

| Thermal expansion co-efficient µm/m°C | 12.2 | ||||

| Thermal conductivity W/(m.K) | 46 | ||||

| Modulus of elasticity 10^3 N/mm2 | 210 | ||||

| Electric resistivity Ohm.mm2 /m | 0.19 | ||||

| Specific heat capacity J/(kg.K) | 460 | ||||

| Modulus of elasticity 10^3 N/mm2 | 100 ℃ | 200 ℃ | 300 ℃ | 400 ℃ | 500 ℃ |

| 205 | 195 | 185 | 175 | 165 | |

| Thermal expansion 10^6 m/(m.K) | 100 ℃ | 200 ℃ | 300 ℃ | 400 ℃ | 500 ℃ |

| 11.1 | 12.1 | 12.9 | 13.5 | 13.9 | |

AISI 4140 steel bar Mechanical Property

| Mechanical Condition | R | S | S | T | U | V | W |

| Ruling Section mm | 250 | 250 | 150 | 100 | 63 | 30 | 20 |

| Tensile Strength Mpa | 700-850 | 770-930 | 770-930 | 850-1000 | 930-1080 | 1000-1150 | 1080-1230 |

| Yield Strength Mpa Min | 480 | 540 | 570 | 655 | 740 | 835 | 925 |

| Elongation % | 15 | 13 | 15 | 13 | 12 | 12 | 12 |

| Izod Impact J Min | 34 | 27 | 54 | 54 | 47 | 47 | 40 |

| Charpy Impact J Min | 28 | 22 | 50 | 50 | 42 | 42 | 35 |

| Hardness Brinell HB | 201-255 | 233-277 | 233-277 | 248-302 | 269-331 | 293-352 | 311-375 |

AISI 4140 steel bar High Temperature Strength

| For quenched and tempered heavy forgings | |||||||

| Diameter mm | Yield strength MPa | ||||||

| 20 ℃ | 100 ℃ | 200 ℃ | 250 ℃ | 300 ℃ | 350℃ | 400℃ | |

| ≤250 | 510 | 486 | 461 | 441 | 422 | 392 | 363 |

| 250-500 | 460 | 431 | 412 | 402 | 382 | 353 | 324 |

| 500-750 | 390 | 333 | 333 | 324 | 304 | 275 | 245 |

AISI 4140 steel bar Forging

Forging temperature should be carried out between 900℃-1200℃,The lower the forging-ending temperature ,the finer the grain size .Hold the temperature till uniform before forge,minimum forging temperature 850°C,so don’t forge below 850℃.AISI 4140 steel should be cooled as slowly as possible in still air or in sand after forged.

AISI 4140 steel bar Normalizing

Normalizing is used to refine the structure of forgings that might have cooled non-uniformly after forged,and considered as a conditioning treatment before final heat treatment.Normalizing temperature for AISI 4140 steel should be carried out between 870℃-900℃. hold suitable time for the steel to be thoroughly heated to complete the ferrite to austenite transformation.Cool in still air.

AISI 4140 steel bar Annealing

After Forged,AISI 4140 steel may be annealed .Annealing temperature should be carried out between 800℃-850℃, hold suitable time for the steel to be thoroughly heated. Cool slowly in the furnace.This treatment will form a structure suitable for machining.The maximum Hardness is 241 HB.

AISI 4140 steel bar Hardening

This heat treatment will obtain martensite structure after quenched.It should be carried out between 840℃-875℃, hold suitable time for the steel to be thoroughly heated, soak for 10-15 minutes per 25 mm section, and quench in oil, water, or polymer as required.Tempering should be followed immediately after quenched.

AISI 4140 steel bar Tempering

Tempering is usually carried out to relieve stresses from the hardening process, but primarily to obtain the required hardness and mechanical properties. The actual tempering temperature will be chosen to meet the required properties.Heat the AISI 4140 carefully to a suitable temperature ,usually between 550℃-700℃, soak at the temperature for 2 hours per 25mm of ruling section, then cool in air.Tempering between 250℃-375℃ is not avoided as tempering within this range will seriously reduce the impact value,result in temper brittleness .

AISI 4140 steel bar Application

AISI 4140 steel finds many applications as forgings for the aerospace,oil and gas,automotive, agricultural and defense industries etc. Typical applications for 4140 steel uses include:forged gears,spindles,fixtures,jigs,collars,Axles,conveyor parts,crow bars,logging parts,shafts,sprockets,studs,pinions,pump shafts, rams, and ring gears etc

4140 Steel Buying Guide

AISI 4140 steel is a type of low-alloy steel that’s embedded with manganese, molybdenum, and chromium. Unlike other types, 4140 steel isn’t that hard and challenging to distinguish. However, since there are hundreds and hundreds of AISI 4140 steel suppliers and manufacturers, you can find choosing the best one a challenge.

Also, not all 4140 steels are the same. That’s what this particular guide is for! We’ll educate you in terms of how you can choose what 4140 steel to buy and purchase, as well as guide you which manufacturer or supplier to trust!

What is the AISI in 4140 Steel?

The AISI is an acronym or a short term for the American Iron and Steel Institute.

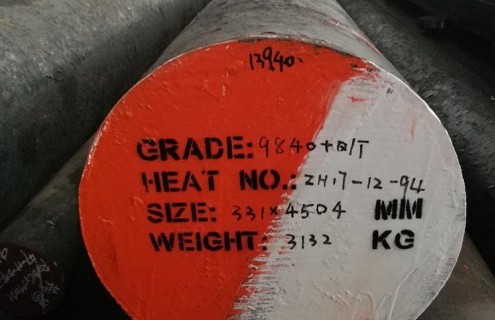

Image of AISI 4140 steels placed being prepared for distribution

It signifies the procedure or the method of how a certain type of steel was made.

So, you can think of the AISI 4140 steel to be a steel that has been processed through their terms.

What’s the Chemical Composition of 4140 Steel?

To start off, it is imperative for us to know the composite of AISI 4140 steel.

It is actually comprised of the following elements:

- Iron (Fe) – Balanced

- Phosphorus (P) – 0.035%

- Silicon (Si) – 0.15 to 0.30%

- Sulfur (S) – 0.040%

- Carbon (C) – 0.389 to 0.430%

- Manganese (Mn) – 0.75 to 1.0%

- Chromium (Cr) 0.80 to 1.10%

These are the elements and the composites that make up AISI 4140 Steel. You will see some ranges because manufacturers put and combine them differently.

For instance, there are some manufacturers that only mix in 0.90% of Manganese and the full 1.10% of Chromium, and so on.

What Do the Grade Numbers in 4140 Steel

Have you ever wondered why it was called as 4140 steel in the first place? You might have thought of it as a systematic process, but there’s actually deeper meaning into it.

The first number, which is the number four (4), implies that the AISI 4140 steel is made up of substantial amounts of molybdenum than other types of steel.

Following that, the number one (1), tells the story that the AISI 4140 steel contains additional elements such as chromium, manganese, etc. You can see that in other types of steels too such as the 4340 steel.

Lastly, the last two (2) numbers, which is the number 40, is the sign that’s used in differentiating the carbon content from other types of steel.

What are the Properties of 4140 Steel?

Akin to the different types and kinds of steel, AISI 4140 steel contains physical, mechanical, and thermal properties as well.

4140 steel is hard, that’s why it can be used for percussion applications

To help you, we’ll only be discussing both the mechanical and the physical properties. We would be skipping thermal properties so you can avoid confusion.

Physical Properties

- Melting Point – 1,416 degrees Celsius

- Density – 7.85 g/cm3

Mechanical Properties

- Yield Strength – 415 MPa

- Bulk Modulus – 140 GPa

- Tensile Strength – 655 MPa

- Hardness (Brinell) – 197

- Hardness (Rockwell C) – 13

- Machinability – 65

These are the physical and the mechanical properties of AISI 4140 steel!

IS AISI 4140 Steel Hard Enough?

The answer to this question will depend on what type of use you’ll be doing with it.

AISI 4140 steel is hard that it’s possible to be used on a wide range of applications

Since AISI 4140 steel is a type of steel that contains medium-carbon levels, it is quenched to so that it can reach hardness levels that range between 54 and 59.

On the contrary, pre-heated and pre-hardened AISI 4140 steel is treated to a medium-level hardness between 28 and 32 HRC. You can then choose to anneal it so that it can reach up to 30 RC.

How Do Manufacturers Produce 4140 Steel?

You can produce and manufacture AISI 4140 steel by mixing and combining alloying elements. These elements include iron, carbon, and molybdenum as the base.

Quenching – one of the processes in producing AISI 4140 steel

Then, you can choose to add chromium, manganese, silicon, phosphorus, and other elements.

The first step in producing and in manufacturing 4140 steel is by melting the base elements into an oxygen or an electric furnace. Then, they’re cooled and annealed (with the possibility of being annealed multiple times).

After the annealing procedure, it’s heated again to its molten state. You’ll then have to pour it into the form you wish to, and you can work on it via hot or cold rolling.

That’s the general structure of how 4140 steel is made and manufactured.

Where is AISI 4140 Steel Used?

You can use AISI 4140 steel in a lot of different applications.

These are some of the customary applications of AISI 4140 steel

These applications include, but are not limited to the following:

- Collars

- Spindles for milling machines

- Bolts and Nuts (Tools)

- Gears

- Jigs

- Steel Coupling

- Fixtures

- Covers

- Slides

- Rollers and Conveyors

- And Many More!

You can use 4140 steel in different ways, thanks to its good hardness levels and penetration. More so, you can also trust its ductility and overall wear resistance!

So, if you think that AISI 4140 steel is something that’s only usable in certain situations, think again!

The question is, where can you get the best and the highest levels of 4140 steel?

Is 4140 hardened steel?

AISI 4140 is an ideal chromium molybdenum through-hardened tooling steel with the ability to be heat treated and tempered up until it reaches 43 HRC on some properties. It can also take low alloy additions without losing performance, making this a versatile metal that will suit most applications well while still being tough enough when you need more strength or impact resistance from your tools.

Is 4140 considered tool steel?

4141 is a type of tool steel with high chromium and carbon content. It can be used to make tools or machines that need extra durability, like coal miners’ pliers!

Which is harder 1018 or 4140 steel?

It can be a challenge to choose the best material for your next project. 1018 steel has many valuable properties that make it preferable, like its machinability and weld ability; but 4140 is stronger in some cases where you need high impact resistance or fatigue/torsion strength with little cost increase over carbon steels (which are not always feasible).

Is 4140 steel a type of stainless?

Yes, it is. 17-4 PH martensitic stainless steels can be heat treated to fit the material properties needed for many applications and processes – making them an excellent choice!

Can 4140 be water quenched?

Water-quench steel will achieve a higher as-quenched hardness than oil-quench. For the recommended heat treatment, we typically include heating to austenitizing temperature and then oil or air cooling it before applying annealing at lower temperatures (below 1500°F). Tempering is necessary if you want your products in this material type with desired range of strengths.

Is 4140 steel good for shafts?

Yes! This material has high fatigue strength, excellent toughness and it’s often used in crankshafts because of its toughness. There are lots more reasons why this kind of metal makes the best choice when you want something that can last long but there some drawbacks too – like corrosion resistance which isn’t ideal if your goal is water-cooling on top (though probably not an issue with today’s technology).

Is 4140 hot rolled or cold rolled?

4140 Hot Rolled Steel Bar

4140 hot rolled steel bar is a medium-carbon alloy that has the ability to be hardened. The high hardenability comes from its mix of other elements, which are what make this grade so useful for forging or heat treating after rolling it into shape with hammering specific tools on an industrial press machine. It also resists fatigue and impact damage very well once treated in some way because there’s no need for case hardening since every surface gets pounded until you get just about whatever amount needed–this means less time wasted while waiting around at home wondering how long everything will take!

What is the difference between 4130 and 4140 steel?

AISI 4140 alloy has greater hardenability, strength, ductility (it can be drawn) but it’s slower to heat treat than A4143. It’s also easy welding process that doesn’t give off much heat; this means less chances for distortion in already heated metal because its not as dangerous when welding them somewhere like near an engine where there could be high temperatures inside cars).

4130 contains 0.28%-0 .33% carbon while being stronger then normal Low percentage of manganese creates tougher material with good wear resistance properties too! This makes up most components used by auto makers today due.

What is the difference between 4140 and 4150 steel?

The difference between 4140 and 4150 steel is that the former has a higher tensile strength, meaning it can withstand more stress before breaking. It also allows for easier bending whereas ductility in 4140 makes this material better suited to cold working conditions as well as those which require high temperatures such as forming operations where4150 must first undergo thermal treatment like heating up its material ahead of time so you know what type (or thickness) will be needed by your project at hand; but because we all want our projects completed quicker than they take place–therefore saving money!–we use an alternative form or process:annealing!

To make things even simpler: -4xxx steels represent Carbon basically through any other chemical.

Which 4140 Steel Manufacturer Should You Trust?

There may be hundreds to thousands of AISI 4140 steel manufacturing companies today. However, choosing to work with us here at Waldun steel can take your heat off of the situation.

Apart from being the most trusted 4140 steel wholesaler in China, we’re also in partnership with world-renowned businesses and conglomerates!

With Waldun Steel, you’ll not only get high quality AISI 4140 steel, you can also get custom 4140 steels perfect for your needs!

All you need to do is to pick up the phone and dial our contact number! You can also choose to shoot us an email! Don’t worry about rates and prices – we’ll give a free quotation to you!

Related Steel Products

Page Contents

- AISI 4140 Steel Bar Supply Form & Size & Tolerance

- AISI 4140 steel bar Chemical Composition

- AISI 4140 steel bar Physical Property

- AISI 4140 steel bar Mechanical Property

- AISI 4140 steel bar High Temperature Strength

- AISI 4140 steel bar Forging

- AISI 4140 steel bar Normalizing

- AISI 4140 steel bar Annealing

- AISI 4140 steel bar Hardening

- AISI 4140 steel bar Tempering

- AISI 4140 steel bar Application

- 4140 Steel Buying Guide

- What is the AISI in 4140 Steel?

- What’s the Chemical Composition of 4140 Steel?

- What Do the Grade Numbers in 4140 Steel

- What are the Properties of 4140 Steel?

- IS AISI 4140 Steel Hard Enough?

- How Do Manufacturers Produce 4140 Steel?

- Where is AISI 4140 Steel Used?

- Is 4140 hardened steel?

- Is 4140 considered tool steel?

- Which is harder 1018 or 4140 steel?

- Is 4140 steel a type of stainless?

- Can 4140 be water quenched?

- Is 4140 steel good for shafts?

- Is 4140 hot rolled or cold rolled?

- What is the difference between 4130 and 4140 steel?

- What is the difference between 4140 and 4150 steel?

- Which 4140 Steel Manufacturer Should You Trust?

- Related Steel Products