20MnCr5 / 1.7147 Steel

20MnCr5/1.7147 Alloy steel manufacturers and suppliers, supplied in round rods,square/flat bars,rollers,shafts,blocks and forging pieces.

20MnCr5/1.7147 Alloy steel a Chromium-Manganese steel according to DIN standard which has tensile strength and wearing resistance after QT heat treatment.It is widely used in piston bolts, spindles, camshafts, gears, shafts and other mechanical controlling parts.

20MnCr5, also known as 1.7147 steel in the DIN standard, is a case-hardening alloy steel renowned for its exceptional wear resistance, toughness, and strength. This steel is widely used in industries requiring components with hardened surfaces and tough cores, such as automotive, machinery, and power transmission.

What is 20MnCr5 / 1.7147 Steel?

20MnCr5 is a low-carbon alloy steel with added manganese and chromium to enhance its mechanical properties. It is primarily used for carburizing applications where a hard, wear-resistant surface is desired while maintaining a tough core to withstand mechanical stress.

Chemical Composition

The chemical composition of 20MnCr5 ensures its suitability for case-hardening and wear-resistant applications:

| Element | Content (%) |

|---|---|

| Carbon (C) | 0.17–0.22 |

| Silicon (Si) | ≤ 0.40 |

| Manganese (Mn) | 1.10–1.40 |

| Chromium (Cr) | 0.80–1.10 |

| Phosphorus (P) | ≤ 0.025 |

| Sulfur (S) | ≤ 0.035 |

The combination of manganese and chromium improves hardenability, wear resistance, and strength while maintaining excellent ductility.

Mechanical Properties

20MnCr5 steel’s mechanical properties are tailored through heat treatments such as carburizing and quenching:

| Property | Core (After Carburizing) | Case (After Carburizing) |

|---|---|---|

| Tensile Strength | 600–800 MPa | 1,200–1,800 MPa |

| Yield Strength | 400–500 MPa | N/A (Case Hardened) |

| Elongation at Break | 8–12% | Low |

| Hardness | 180–240 HB | 58–62 HRC |

| Toughness | High | Moderate |

The hardened case provides excellent wear resistance, while the tough core ensures resistance to fatigue and impact.

Key Features and Advantages

- Excellent Wear Resistance:

- The carburized case provides a hard, durable surface for components subjected to high friction.

- High Toughness:

- The tough core ensures that components resist fatigue and impact, even under heavy loads.

- Good Machinability:

- In its annealed state, 20MnCr5 is easy to machine, allowing for precise component manufacturing.

- Hardenability:

- Chromium enhances hardenability, making it suitable for complex geometries.

- Cost-Effectiveness:

- Provides an economical solution for components requiring both wear resistance and strength.

Applications of 20MnCr5 / 1.7147 Steel

Due to its properties, 20MnCr5 steel is extensively used in a wide range of industries:

- Automotive Industry:

- Gears, camshafts, crankshafts, and transmission components.

- Machinery Manufacturing:

- Wear-resistant bushings, shafts, and pinions.

- Power Transmission:

- Sprockets, couplings, and other high-stress components.

- Construction Equipment:

- Linkages and moving parts subjected to friction and wear.

Heat Treatment of 20MnCr5

Heat treatment processes are critical for optimizing the properties of 20MnCr5 steel:

- Carburizing:

- Performed at 880–920°C to introduce carbon into the surface layer, followed by quenching to create a hard surface while keeping the core tough.

- Quenching and Tempering:

- Quenching at 820–860°C, followed by tempering at 150–200°C to relieve stresses and improve toughness.

- Annealing:

- Conducted at 650–700°C to improve machinability by softening the steel.

- Normalizing:

- Heating to 860–900°C, followed by air cooling, refines the grain structure and enhances uniformity.

Processing Techniques

- Machining:

- Machinability is excellent in the annealed condition, allowing for precision machining.

- Welding:

- Weldability is moderate. Preheating and post-weld heat treatment are recommended to avoid cracking.

- Forging:

- Performed at 900–1,200°C, followed by air cooling or annealing to achieve the desired properties.

Comparisons with Similar Grades

| Steel Grade | 20MnCr5 (1.7147) | 16MnCr5 (1.7131) | 8620 Steel |

|---|---|---|---|

| Carbon Content | Higher (0.17–0.22%) | Lower (0.14–0.18%) | Moderate (0.18–0.23%) |

| Case Hardness | Higher | Moderate | Similar |

| Core Toughness | High | Slightly Higher | High |

| Applications | Heavy-duty gears | General gears | Automotive components |

Certifications and Standards

20MnCr5 steel is produced in compliance with various global standards:

- DIN EN 10084: Case-hardening steels – Technical delivery conditions.

- ISO 683-3: Heat-treatable and alloy steels for carburizing.

- ASTM Standards: Equivalent grades under ASTM for international use.

20MnCr5 / 1.7147 Steel – The Comprehensive FAQ Guide

If you’ve been in the steel industry for quite some time now, then you know the importance and the significance of the 20NbCr5 or 1.7147 steel.

Should you be unsure of what it is, you’re just on the right page! In this FAQ guide, we will be waking you through what 20MnCr5 or 1.7417 steel is. Moreover, we will also help you identify it from other types of steel that are the closest.

By the end of this particular guide, you will be an expert in determining the 1.7417 or 20MnCr5 steel manufacturer you should work with.

What is 20MnCr5 Material?

It is a type of steel that’s casehardened that contains lower levels of carbon content.

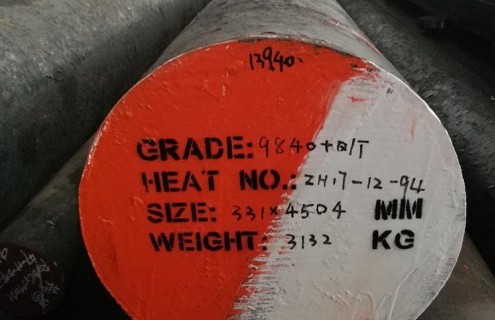

Image of what 20MnCr5 material looks like in round bars

Moreover, you can also expect it to have decent levels of hardenability as well as wear resistance and ductility.

Its composition has an alloying element, which is chromium, and you have the option to harden and make it stronger up to a total hardness level of HRC 41.

This particular steel type is the most ideal for parts and components that are required to be at a strength level of 1,000 to 1,300 N/mm2.

What is Case Hardening?

Case hardening simply is a material processing methodology you would want to use to increase and heighten the hardness level of a certain material for the outer surface of it.

Case hardening of steel

Performing case hardening would most likely result to a thin layer of metal that is harder and tougher than the metal volume below the hardened layer.

Basically, it’s a process that helps produce a wear-resistant surface all the while maintaining strength and toughness at the core of a material.

What Can You Use 20MnCr5 / 1.7145 Steel For?

Stacks of round bars of 20MnCr5 / 1.7147 steel

To name a few of the most customary applications you can use 20MnCr5 / 1.7147 steel for include:

- Camshafts

- Shafts

- Gears

- Spindles

- Piston Bolts

- Boxes

- Mechanical Controlling Parts

- And Many More!

Thanks to its good-to-moderate wear resistance, you can find many uses for 20MnCr5 steel no matter what type of industry and sector you are in!

You can use 20MnCr5 steel to make and create goods where the surface of it is subject to thermochemical or thermal treatment. In addition to that, you can find it suitable for engineering and mechanical parts!

Is 20MnCr5 and 5120 Steel the Same?

5120 steel is one of 20MnCr5’s equivalent materials; 20MnCr5 is from China, while 5120 steel is from the United States (U.S.).

Thin example of 5120 steels

They are equivalent materials, however, it doesn’t necessarily mean that they share identical alloying element content.

What is C35 Steel?

C35 steel is a type of steel that contains medium level of carbon content.

C35 steel in round bars

Unlike 20MnCr5, C35 is a moderate-level carbon steel that you can use for a wide array of applications, but mostly, it’s for the parts and components of machines and equipment.

It boasts of its excellent state of being forged, machinability, and weldability.

20MnCr5 vs. 16MnCr5 Material

The most common misconception that people have with 20MnCr5 and 16MnCr5 is that they’re just the same. And while they’re both alloyed steels for case hardening, they’re not actually the same.

20MnCr5 is a steel grade that is low-alloyed. In the same way, 16MnCr5 falls under the same category.

16MnCr5 is a type of steel that contains carbon levels that range between 0.14 and 0.19%, while 20MnCr5 has about 0.17 to 0.22%. This difference in carbon is actually big, especially because of the fact that carbon is the main component in contributing to the hardness or the toughness of the steel.

While that is the case, 20MnCr5 and 16MnCr5 are similar in terms of normalizing, annealing, and carburizing.

What is EN31 Steel?

EN31 steel is a type of steel that has high levels of strength. In addition to that, EN31 is a type of steel alloy that you would harden and temper before supplication.

Raw EN31 round bar steels

Furthermore, EN31 steel is a type of steel that contains too few alloying elements such as molybdenum (Mn), chromium (Cr), nickel (Ni), and more. These elements are what makes the wear resistance, tensile strength, durability, and ductility at its peak!

The base hardness of EN31 steel is at 24 HRC, which is typically at the moderate-to-low hardness compared to its counterparts.

What Are Equivalent Materials of the 20MnCr5 / 1.7417 Steel?

The equivalent materials and steels of 20MnCr5 or 1.7417 steels include:

- USA – 5120

- Germany – 1.7417

- Japan – SMnC420H

What Are the Mechanical Properties of 20MnCr5 / 1.7147 Steel?

The mechanical properties are the physical properties of the steel wherein it shows its capabilities when forces are applied.

It is imperative to be aware of the mechanical properties of steels before deciding on them, why? – Because you can consider that as your basis on whether or not the steels will be able to fit your needs and requests.

20MnCr5 or 1.7147 Steel’s Mechanical Properties

- Tensile Strength: 520 MPa

- Yield Strength: 415 MPa (Minium)

- Bulk Modulus: 140 GPa

- Shear Modulus: 80 GPa

- Thermal Conductivity: 46.6 W/mK

8620 Steel and What is it Used For?

From the designation of the steel alone, you would know that it’s not a type of steel that’s made and manufactured in China.

Example of what 8620 steel looks like

It’s a standard that’s been made and created in the U.S. Furthermore, it is a low-carbon type of case-hardening steel that contains various alloying elements, wherein its base include nickel, chromium, and molybdenum.

Similar to that of 20MnCr5 / 1.7147 steel, you can use the 8620 alloy to produce and manufacture parts and components that have good levels of wear resistance, including ring gears, crankshafts, shafts, fasteners, enclosures, and many more!

It shares almost the same properties to the USA counterpart of 20MnCr5 or 1.7147 steel, it just contains added alloying elements in the process.

20MnCr5 Material Price

Determining the price of 20MnCr5 / 1.7147 is difficult – or rather quite impossible. What you might get online might not be accurate and precise, causing you to have problems with the budget.

The best thing to do in this case is to contact and ask a particular 20MnCr5 / 1.7147 manufacturer. More often than not, they will grant you a free estimate or a free quote.

In addition to that, if you’re going to purchase 20MnCr5 steel wholesale, you will be able to get better and more considerable rates and prices for it.

So, never assume that all manufacturers and suppliers will ask for the same price. Have the expectation that it will always be different.

20MnCr5 Steel Composition

Knowing what a particular steel grade is comprised of will be one of the best and the most essential things to figure out if a particular steel grade is for you.

Here’s a table of the chemical composition of the 20MnCr5 / 1.7147 steel:

| Carbon (C) | Chromium (Cr) | Manganese (Mn) | Phosphorus (P) | Sulfur (S) | Silicon |

| 0.17 to 0.22% | 1.00 to 1.30% | 1.10 to 1.40% | ≤0.035% | ≤0.035% | ≤0.4% |

With this table, you can easily recognize and distinguish whether or not 20MnCr5 / 1.7147 steel is the type of steel for you.

To help you further with what each of these alloying elements contribute to the overall steel, they are:

Chromium

Having chromium means that a particular material’s rusting or oxidation-resistance levels are more and are better. This happens because instead of the steel surface oxidizing, the chromium oxidizes first and will form a protective layer of the steel.

Manganese

The more manganese a steel has, the harder, stronger, and the more durable it is. The major downside of having high levels of manganese is the fact that it’ll have a slower rate of quenching.

Phosphorus

Phosphorus contributes to the strength and hardness of a particular steel or material. If your steel has high levels of phosphorus, you can expect it to have increased hardness, strength, and an enhanced machinability.

Silicon

What Silicon (Si) does on steels is that it increases both the yield and the tensile strength. Due to this, the forgeability, hardness, as well as the permeability of the steel is enhanced and developed, too.

Sulfur

Sulfur decreases the weldability of a particular steel, while it develops the machinability. Sulfur is carefully added onto steels because if it’s added without enough levels of manganese, it’ll become less ductile, less tough, and it’ll produce red heat brittleness.

Those are the primary alloying elements that 20MnCr5 / 1.7147 steel has, but that’s not the complete list of alloying elements present. There are others and there are a lot more!

What is the HRC Hardness of 20MnCr5 / 1.7417 Steel?

The HRC hardness that 1.7417 / 20MnCr5 steels can reach up to a maximum of 60 to 66 via salt-bath furnace and oil quenching.

However, if you choose to have it air-cooled, it can arrive at an HRC hardness levels that range between 22 and 30 HRC.

Can You Trust 20MnCr5 / 1.7417 Chinese Steel Manufacturers?

Yes, there are a lot of businesses that trust and rely on 20MnCr5 or 1.7417 Chinese steel manufacturers.

As a matter of fact, most of them are from the West like the Americas or Europe. Getting in work with a Chinese manufacturer of 20MnCr5 steel is like getting the best and the highest quality you can get in the cheapest and the most affordable rates.

20MnCr5 Steel Supply Forms

What type of shapes, forms, and sizes can you purchase 20MnCr5 or 1.7147 steel in? Supply forms, for the benefit of everyone, are the forms or shapes you can purchase a specific steel or metal in.

Akin to other types of steel, you can purchase 20MnCr5 / 1.7147 steel in many different supply forms and shapes. The most common ones include, but are not limited to:

- Round Bars or Round Steels

- Sheet Steels

- Square Bars or Square Steels

- Plates

But, of course you can always opt to go with custom 20MnCr5 / 1.7147 steel if you want all of your products to be specific to whatever your business needs are!

One good tip before choosing a manufacturer is to ask them if they’re offering 20MnCr5 / 1.7147 steel that can be custom-made or specific to the needs of clients. 9 times out 10, they’ll agree to it, however, there are some that don’t.

It’s always better to be safe than sorry!

Which Chinese 1.7417 or 20MnCr5 Steel Supplier Should You Trust?

Out of all the many Chinese 20MnCr5 suppliers in the market, we here at Waldun Steel are deemed and considered to be the best and the most trusted.

Waldun Steel has been considered to be the epitome of excellence when it comes to steel manufacturing. Apart from 20MnCr5 or 1.7417 steel, you can also count on us to help you with other steel types and grades, such as AISI 4140 alloy steel, AISI 1020 carbon steels, EN 41B nitriding steels 30CrNiMo8 / 1.6580 steel, and many more!

There’s no limit as to what you can get when you choose Waldun Steel as your manufacturer!

Why Work With Waldun Steel?

Apart from us being the best, the most experienced, and the most skilled, we’re also the 20MnCr5 / 1.7147 steel manufacturer that you can trust because all of our equipment and machinery have undergone extreme tests.

In addition to that, our company is also equipped with the most advanced technologies and calibration processes, guaranteeing you nothing but higher-quality 20MnCr5 steel products for the most affordable and commendable rates.

Get a Free Quote!

Don’t worry about how much budget you’ll need because we wouldn’t make you guess. Waldun Steel will already give you the estimate or the quotation that you need!

Contact us today by dialing our hotline or by giving us a call! We will be more than happy to help you!

Other Related Steel

Page Contents

- What is 20MnCr5 / 1.7147 Steel?

- Chemical Composition

- Mechanical Properties

- Key Features and Advantages

- Applications of 20MnCr5 / 1.7147 Steel

- Heat Treatment of 20MnCr5

- Processing Techniques

- Comparisons with Similar Grades

- Certifications and Standards

- 20MnCr5 / 1.7147 Steel – The Comprehensive FAQ Guide

- What is 20MnCr5 Material?

- What is Case Hardening?

- What Can You Use 20MnCr5 / 1.7145 Steel For?

- Is 20MnCr5 and 5120 Steel the Same?

- What is C35 Steel?

- 20MnCr5 vs. 16MnCr5 Material

- What is EN31 Steel?

- What Are Equivalent Materials of the 20MnCr5 / 1.7417 Steel?

- What Are the Mechanical Properties of 20MnCr5 / 1.7147 Steel?

- 20MnCr5 or 1.7147 Steel’s Mechanical Properties

- 8620 Steel and What is it Used For?

- 20MnCr5 Material Price

- 20MnCr5 Steel Composition

- What is the HRC Hardness of 20MnCr5 / 1.7417 Steel?

- Can You Trust 20MnCr5 / 1.7417 Chinese Steel Manufacturers?

- 20MnCr5 Steel Supply Forms

- Which Chinese 1.7417 or 20MnCr5 Steel Supplier Should You Trust?

- Why Work With Waldun Steel?

- Other Related Steel