1.3355 / HS18-0-1 High Speed Steel

1.3355 / HS18-0-1 High Speed Steel

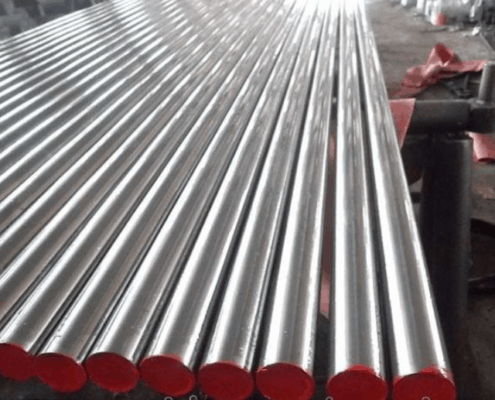

1.3355/HS18-0-1 high speed tool steel manufacturers and suppliers, supplied in round rods,flat/square bars,plates,sheets,wire and blocks.

1.3355/HS18-0-1 is a typical Tungsten-type high speed tool steel which has a high hardness of HRC63~66 after heat treatment. It is not easy to overheating because of its wide heat treatment quenching. The high temperature plastic of 1.3355/HS18-0-1 tool steel is poor,but the wearability is good.

1.3355/HS18-0-1 steel also has good cutting performance which is suitable for cutting tools such as twist anchor, broach, tapping, milling wash,reamer.

Chemical Composition per EN ISO 4957 (High Speed Steel)

| GRADE | NUMBER | C | Si | Mn | P | S | Cr | Mo | V | W |

| HS18-0-1 | 1.3355 | 0.73-0.83 | ≤ 0.45 | ≤ 0.40 | ≤ 0.030 | ≤ 0.030 | 3.80-4.50 | – | 1.00-1.20 | 17.20-18.70 |

Related Specification

AISI/ASTM: T1

JIS/KS: SKH2

UNS: T12001

Heat Treatment

Annealing

1.Annealing is recommended after hot working and before re hardening

2.Heat the temperature to 850°C at a rate of no more than 220°C per hour.

3.Hold at the temperature for one hour per inch of thickness(at least two hours).

4.Cool slowly in the furnace or in air to ambient temperature.

5.The resultant hardness achieved should be Max 255HB or lower.

Hardening

1.Preheat 1.3355/HS18-0-1 to 480°C ,then up to 880°C.

2.Heat to the final hardening temperature of 1250°C and make sure the material must be heated through.

3.Quench in the warm oil,and then complete the quench in air.(care must be taken at this step)

4.1.3355/HS18-0-1 tool steel is suitable for vacuum hardening.

Tempering

1.Tempering must be done immediately after quenching.

2.Heat thoroughly and uniformly to the tempering temperature

3.Hold at the temperature for at least two hours (one hour per inch of the total thickness).

4.Triple tempering is strongly recommended for 1.3355/HS18-0-1 tool steel.

Delivery Condition

| Shape:Round / Square / Flat Bars, Sheet, Plate,Wire. Surface Condition:Black/Turning/grinding |

||||

| Round bar | ||||

| Diameter | 1-16mm | 10-50mm | 50-180mm | 180-300mm |

| Process | Cold Drawn | Hot Rolled | Hot Forged | Free Forging |

| Flat bar | ||||

| Thickness | 1-2.5mm | 1.5-20mm | 20-300mm | |

| Width | Max 800mm | Max 800mm | Max 800mm | |

| Process | Cold Drawn | Hot Rolled | Hot Forged | |

Quality Assured Supply

1.3355/HS18-0-1 high speed steel is supplied in accordance with our ISO 9001 : 2008 registration.